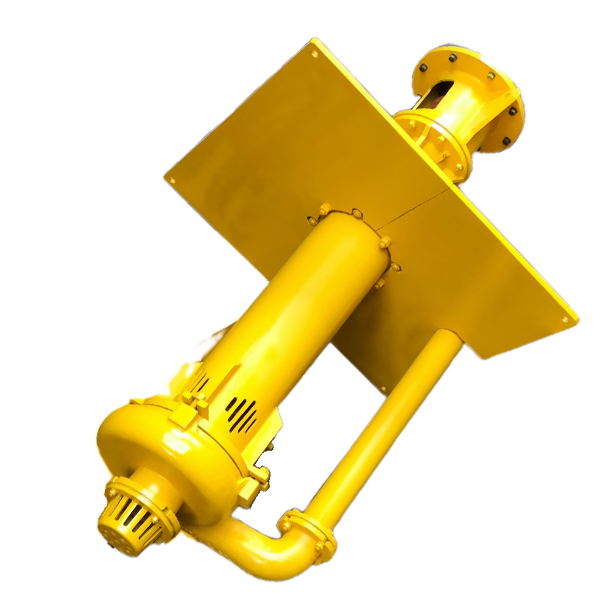

Best quality Underwater Dredger Pump - TG Gravel slurry pump for Pumping sand, Factory direct, quality assurance – Ruite Pump

Best quality Underwater Dredger Pump - TG Gravel slurry pump for Pumping sand, Factory direct, quality assurance – Ruite Pump Detail:

Description

TG Series dredge Gravel Pump are designed to handle very large particles for gravel and dredging operations. This sand pumps are designed for continuous handling of the most difficult higher abrasive slurry, containing solids too large to be pumped by a standard slurry pump.

TG series dredge Gravel Pump are suitable for delivering slurry in mining, explosive sludge in metal melting, grudging in dredger and course of river and other fields.

Feature

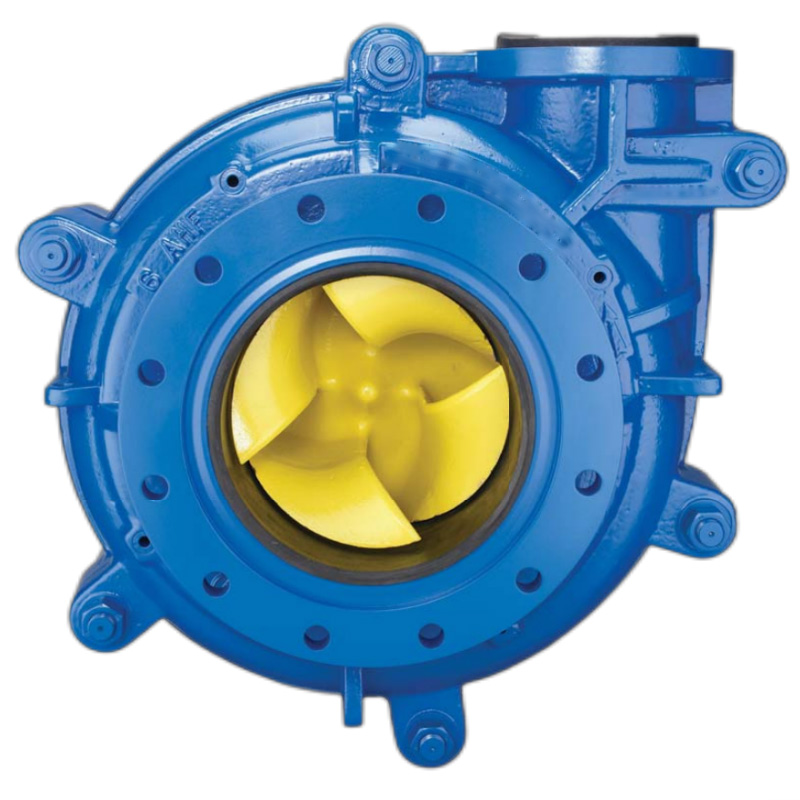

1. Broad path created by single casing and clamp bands connection;

2. Unique design to make maintenance and wet parts replacement convenient;

3. The wet parts are made of Ni-hard and high-chrome wear-resistant alloys with good anti-corrosive property;

4. The discharge direction of pump can be oriented in any direction of 360°;

5. The standard seal type is packing seal.

6. Good performance of NPSH.

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Best quality Underwater Dredger Pump - TG Gravel slurry pump for Pumping sand, Factory direct, quality assurance – Ruite Pump , The product will supply to all over the world, such as: California, Georgia, Brunei, Each product is carefully made, it will make you satisfied. Our merchandise in the production process have got strictly monitored, because it is only to supply you the best quality, we'll feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.