100T-ZGB regrind mill discharge pump

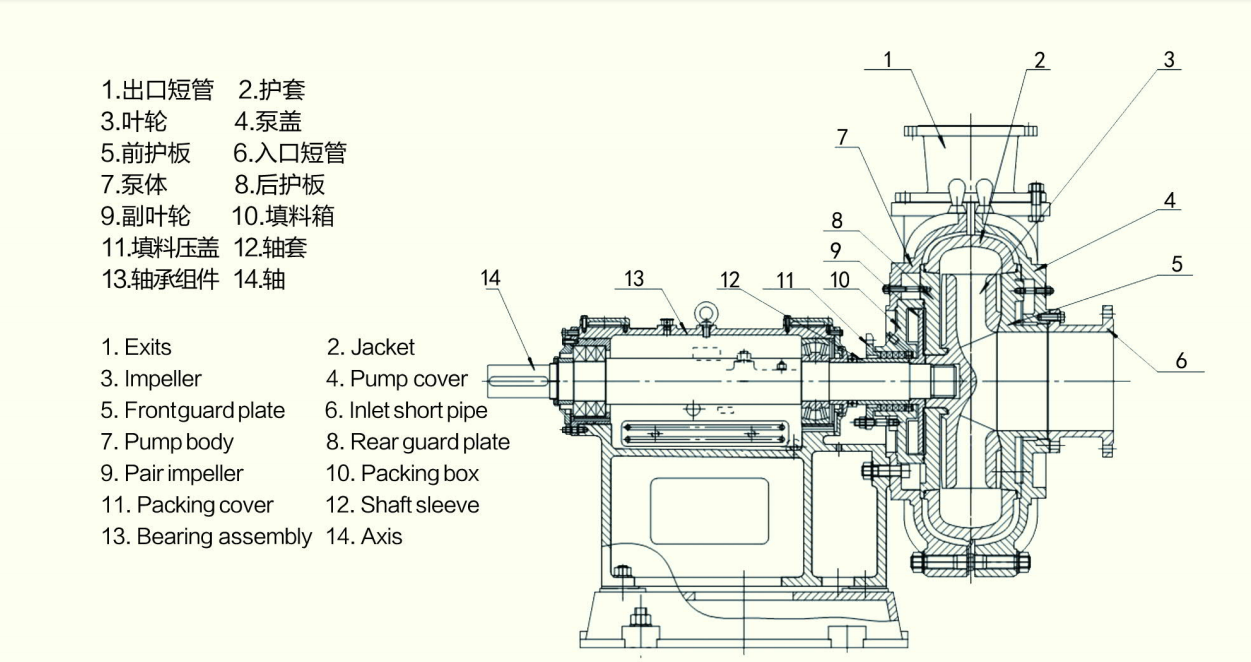

ZGB SLURRY PUMP DETAILS

ZGB type slurry pump has the characteristics of high efficiency, anti-wear, anti-clogging, etc., and has excellent NPSH. With its high ash and sludge handling capabilities, the pump can handle the toughest pumping applications with ease.

Let's delve into the features of this incredible product.

1, ZGB slurry pumps are highly efficient and designed to maximize production while minimizing energy use. Over time, this can lead to significant savings in energy costs, making it a solid investment for any business or industry.

2, the pump is wear-resistant, meaning it can withstand heavy use without degrading over time. This feature ensures that the ZGB slurry pump maintains its peak performance level even after prolonged use.

3, the pump is anti-clog, designed to eliminate any clogging caused by debris or solid particles. This feature ensures a smooth and continuous flow of slurry without any interruption or downtime.

4, the pump has excellent performance in terms of NPSH (Net Positive Suction Head). This feature ensures that the pump can effectively handle low pressure environments, making it an excellent choice for many industries requiring high pressure pumping.

5, ZGB slurry pumps excel at removing ash and sludge thanks to their powerful motors and robust design. This feature makes it ideal for industries such as mining, construction and wastewater treatment.

6, The shaft seal could use the packing seal, expeller seal and mechanical seal.

7,The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

8, There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump.

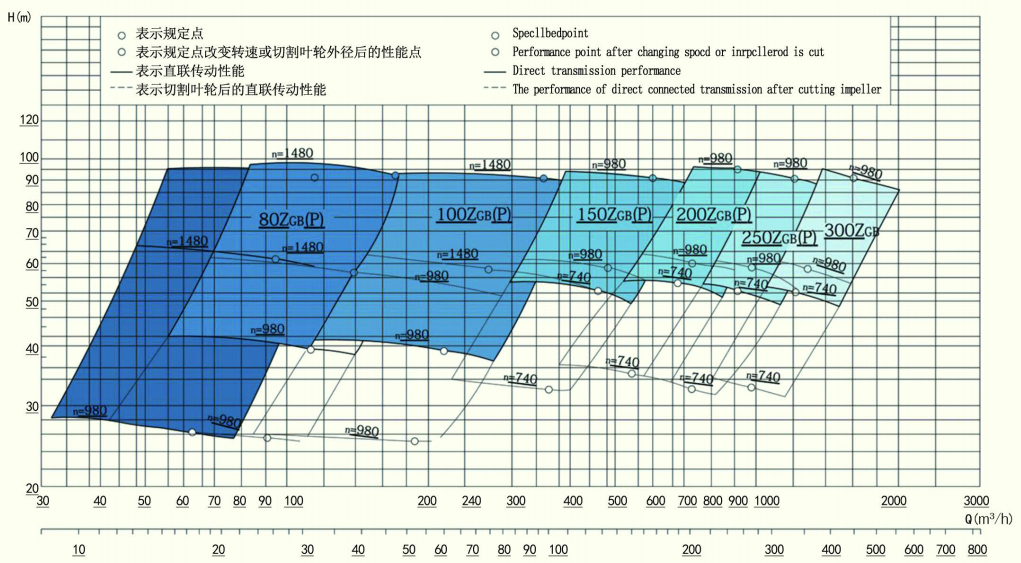

9,Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.

Overall, the ZGB slurry pump is a top-of-the-line product that ticks all the boxes in terms of efficiency, durability and performance. An excellent investment for any industry looking to optimize their pumping systems, its anti-wear and anti-clog features ensure extended product life. Trust ZGB slurry pumps to handle the toughest pumping applications with ease.

ZGB Slurry Pump Technical Data

| Size | Capacity(L/S) | Head(m) | Max.Power(KW) | Speed(r/min) | NPSHm |

| 65ZGB | 10.5-31.7 | 25.4-61 | 33.4 | 980-1480 | 3-5.5 |

| 80ZGB | 15.3-56.7 | 25.6-91.6 | 75.7 | 980-1480 | 2.7-5.2 |

| 100ZGB | 30.9-116.7 | 23.9-91.8 | 124.9 | 980-1480 | 2.6-6.0 |

| 150ZGB | 64.8-200 | 35.2-90.0 | 226.6 | 740-980 | 2.7-3.8 |

| 200ZGB | 97.9-300 | 38-94.2 | 342.9 | 740-980 | 2.7-6.7 |

| 250ZGB | 99.4-378.4 | 36.4-90.1 | 432.1 | 740-980 | 3.3-7.3 |

| 300ZGB | 171.2-533.3 | 34.7-93.4 | 567 | 740-980 | 3.5-6.9 |

ZGB slurry pump application

The pumps can be used in many applications, such as Pipeline transport, High velocity hydraulic transport, Mineral processing, Coal prep, Cyclone feeds, Aggregate processing, Fine primary mill grinding, Chemical slurry service, Tailings, secondary grinding, Industrial processing, Pulp and paper, Food processing, Cracking operations, Ash handling.

ZGB Slurry Pump Package and Shipping

The slurry pump or slurry pump parts will be packed in wooden case.

We will paste the shipping mark on the package according to buyer's requirements.

For more information about our pumps, please send email to: rita@ruitepump.com

Whatsapp: +8619933139867

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |