Best-Selling Slurry Pump Vertical - 65QV-TSP Vertical Slurry Pump – Ruite Pump

Best-Selling Slurry Pump Vertical - 65QV-TSP Vertical Slurry Pump – Ruite Pump Detail:

65QV-TSP Vertical Slurry Pump is designed to handle diverse uses including all rugged mining and industrial applications, always ensuring reliable performance and excellent wear endurance. 65QV-TSP vertical sump pumps are available in various standard lengths to suit common sump depths, offers a wide range of configurations allowing the pump to be tailored to a specific application. Wetted components are available in a wide range of alloys and elastomers. They are ideally suited for handling abrasive and corrosive liquids and slurries while submerged in sumps or pits.

Design Deatures

• Compared to traditional sump pumps, TSP series sump pumps have superb performance in capacity, head and efficiency.

• Unique cantilevered design makes EV series work normally even if the suction volume is not enough.

• Various pump models are available including traditional single-casing pumps as well as pioneering double-casing ones.

• Don’t need any seal and seal water.

65QV-TSP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

TSPeed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

65QV-TSP(R) |

3-30 |

18-113 |

5-31.5 |

700-1500 |

60 |

280 |

15 |

500 |

65QV TSP Vertical Slurry Pumps Applications

The TSP/TSPR verical slurry pumps are available in a wide range of popular sizes to suit most pumping applications. The TSP/TSPR sump pumps are proving their reliability and efficiency worldwide in: minerals processing, coal preparation, chemical processing, effluent handling, sand and gravel and almost every other tank, pit or hole-in-the ground slurry handling situation. The TSP/TSPR pump design with either hard metal (TSP) or elastomer covered (TSPR) components makes it ideal for abrasive and/or corrosive slurries, large particle sizes, high density slurries, continuous or “snore” operation, heavy duties demanding cantilever shafts.

Note:

65 QV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 65 QV-SP vertical slurry pumps and spares.

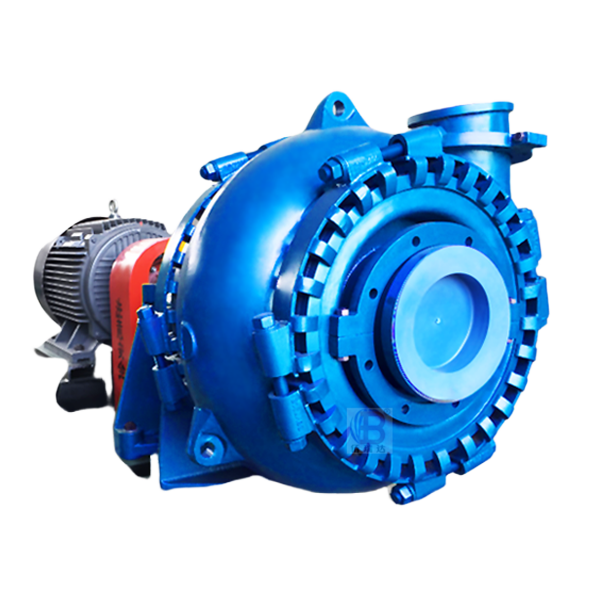

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Best-Selling Slurry Pump Vertical - 65QV-TSP Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Oslo, Kuwait, Barcelona, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.