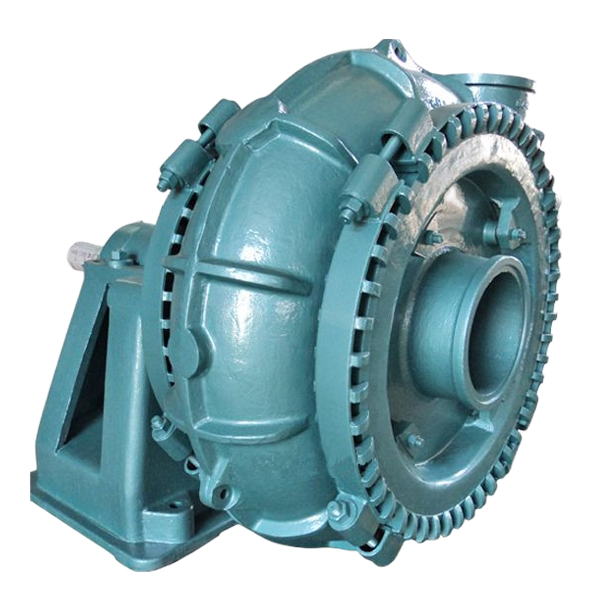

China New Product Pumping Bentonite Slurry - Warman 4/3D-AHR Rubber Slurry Pump spare parts – Ruite Pump

China New Product Pumping Bentonite Slurry - Warman 4/3D-AHR Rubber Slurry Pump spare parts – Ruite Pump Detail:

4x3D-THR Rubber Lined Slurry Pump is the heavy duty slurry pump handling tough and abrasive duties.Rubber slurry pumps are widely used for continuous pumping highly abrasive/dense slurries in processes from cyclone feed to regrind,mill discharge,flotation,mine drainage,dredging of settling lagoons and pumping of drilling mud and tailings in minerals plants and other industrial applications.

Design Features:

√Double casings design centrifugal rubber lined slurry pump,wide passage for solids

√Bearing assembly&frame:Both standard&high capacity types available.

√A large diameter shaft with a short overhang minimizes deflection and vibration.

√Heavy duty roller bearing is housed in a removable bearing cartridge.

√Rubber slurry pump body is fastened with the frame by minimum bolts.

√Slurry pump impeller adjustment is provided in a convenient position below the bearing assembly.

√Slurry pump Impeller&liner material:natural rubber etc

√High efficiency impeller available:up to 86.5%for certain type.

√Interchangeable wet parts material:High chrome alloy metal:PH:5-12;natural rubber:PH:4-12.

√Shaft seal:Packing seal,centrifugal seal,mechanical seal.

√Discharge branch:8 positions in each 45°.

√Driving type:V-belt,flexible coupling,gearbox,hydraulic coupler etc.

4/3 D THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

4/3D-AHR |

60 |

Rubber |

Rubber |

79.2-180 |

5-34.5 |

800-1800 |

59 |

3-5 |

5 |

Rubber Lined Slurry Pumps Applications:

Rubber lined slurry pumps are widely used for Mill discharge,Ni acid slurry,Coarse sand,Coarse tailings,Phosphate matrix,Minerals concentrate,Heavy media,Sugar beet,Dredging,Bottom/Fly ash,Lime grinding,Oil sands,Mineral sands,Fine tailings,Slag granulation,Phosphoric acid,Coal,Flotation,Process chemical,Phosphoric acid etc.

Note:

*4/3 D THR rubber lined slurry pumps and parts are only interchangeable with Warman®4/3 D THR rubber lined slurry pumps and parts.

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for China New Product Pumping Bentonite Slurry - Warman 4/3D-AHR Rubber Slurry Pump spare parts – Ruite Pump , The product will supply to all over the world, such as: Zimbabwe, Guatemala, Kuala Lumpur, We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!