factory customized Sand Pump Backwash - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump

factory customized Sand Pump Backwash - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump Detail:

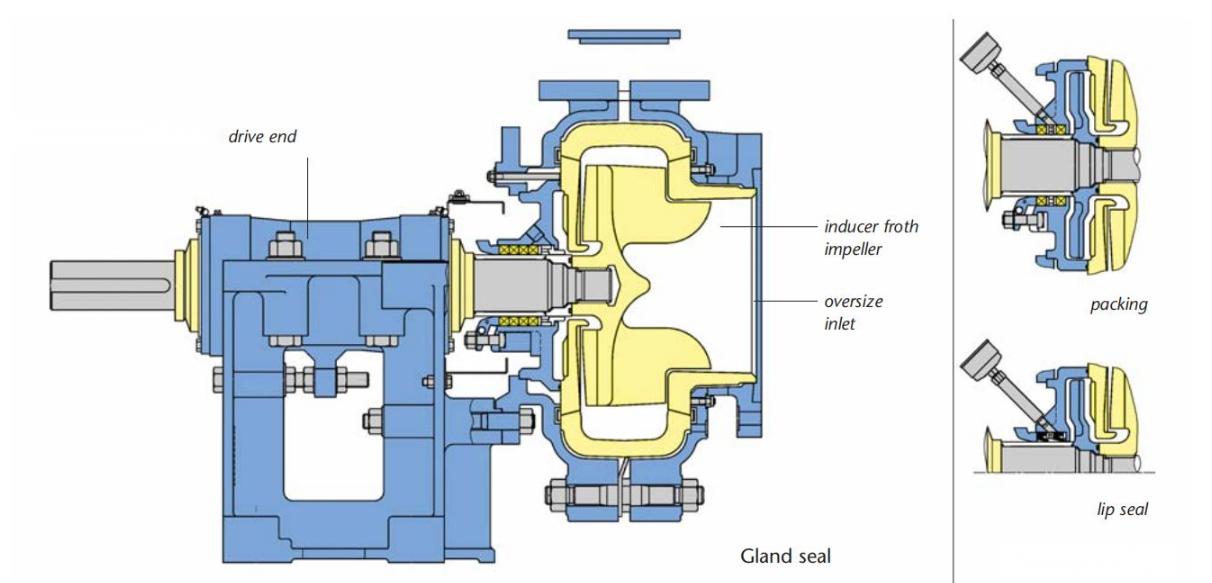

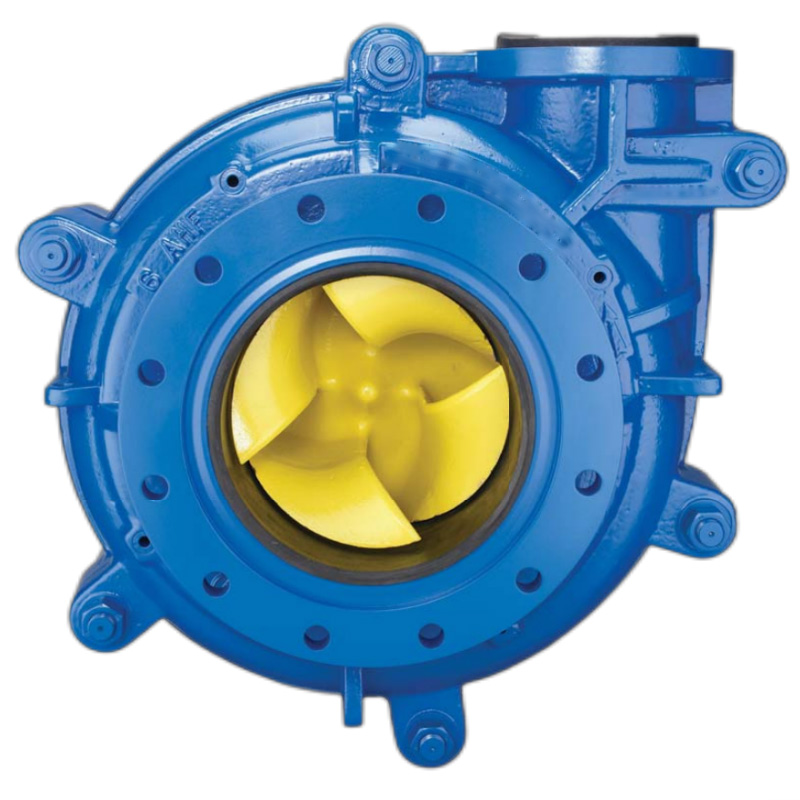

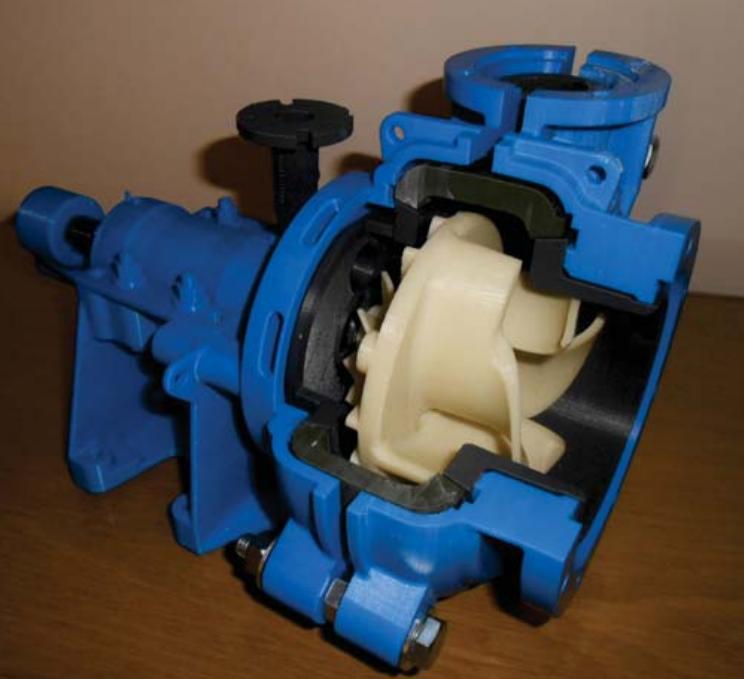

A large oversized inlet with a unique impeller inducer blade can easily handle heavy froth and higher viscosity dense slurry.

The semi-open metal impeller with screw compression function has a high head and is suitable for conveying high air content pulp.

Higher efficiency and lower energy consumption.

Features / Benefits

1.Size range (discharge) :2″ to 22″ (50 mm to 550 mm)

2.Capacities to:20,000 gpm (3,150 m3/hr)

3.Heads to: 120 ft (37 m)

4.Pressures to: 500 psi (3,445 kPa)

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for factory customized Sand Pump Backwash - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump , The product will supply to all over the world, such as: Philippines, New York, Birmingham, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!