Factory Promotional Backwash Sand Pump - 14/12G-TG Gravel Pump, Complete range of pump models – Ruite Pump

Factory Promotional Backwash Sand Pump - 14/12G-TG Gravel Pump, Complete range of pump models – Ruite Pump Detail:

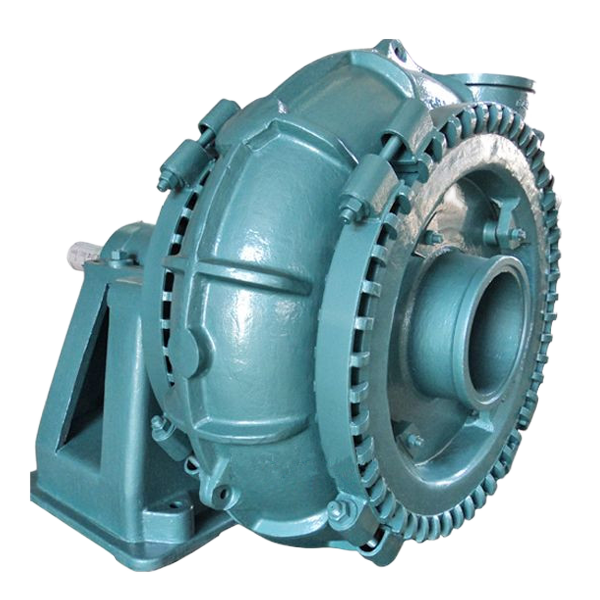

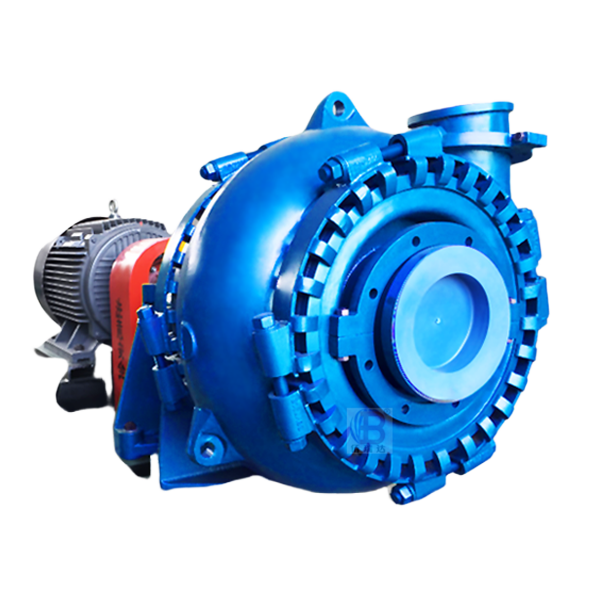

14x12G-TG Gravel Pump is designed for continuously handling the most difficult high abrasive slurries which contain too big solids to be pumped by a standard slurry pump. 14×12 gravel and dredge pumps are suitable for delivering gravels, sands, slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and river course and other fields.

Design Features

• Bearing assembly – Large diameter shaft with short overhang contributes to long bearing life.

• Liners – Easily replaceable liners are bolted, not glued to the casing for positive maintenance.

• Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities.

• Impeller – Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

• Throat bush – Wear is reduced and maintenance simplified by the use of tapered.

14/12G-G Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

14x12G-TG |

600 |

576-3024 |

8-70 |

300-700 |

68 |

2-8 |

864 |

Note:

14x12G-TG gravel pumps and spares are only interchangeable with Warman® 14×12 G-G gravel pumps and spares.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Factory Promotional Backwash Sand Pump - 14/12G-TG Gravel Pump, Complete range of pump models – Ruite Pump , The product will supply to all over the world, such as: Brunei, Portugal, South Africa, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

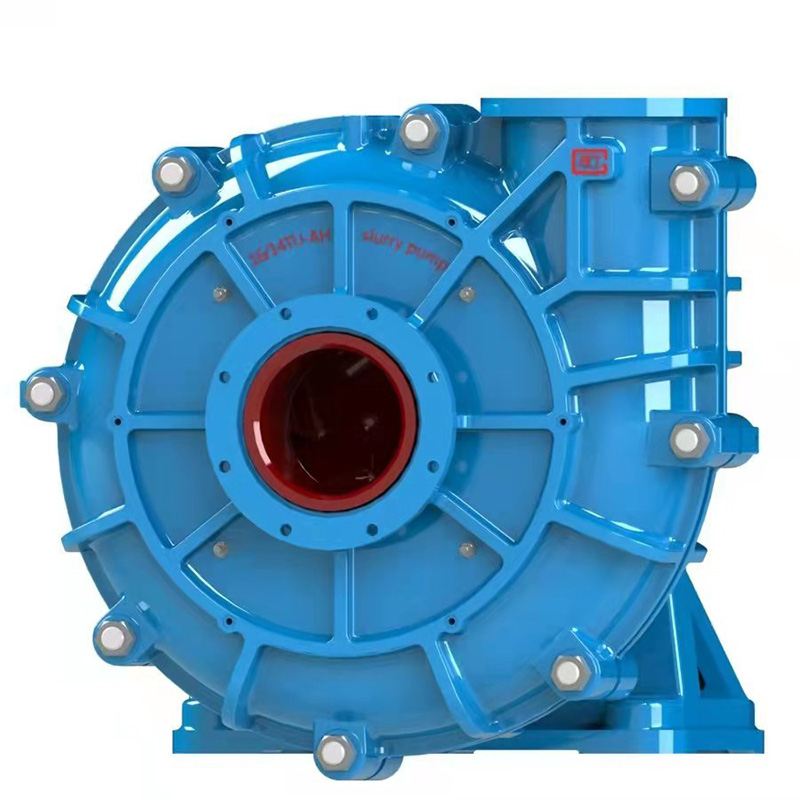

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.