High Quality for Ash Slurry Pumps - 18/16TU-THR Rubber Slurry Pump, Interchangeable anti-abrasive wet parts – Ruite Pump

High Quality for Ash Slurry Pumps - 18/16TU-THR Rubber Slurry Pump, Interchangeable anti-abrasive wet parts – Ruite Pump Detail:

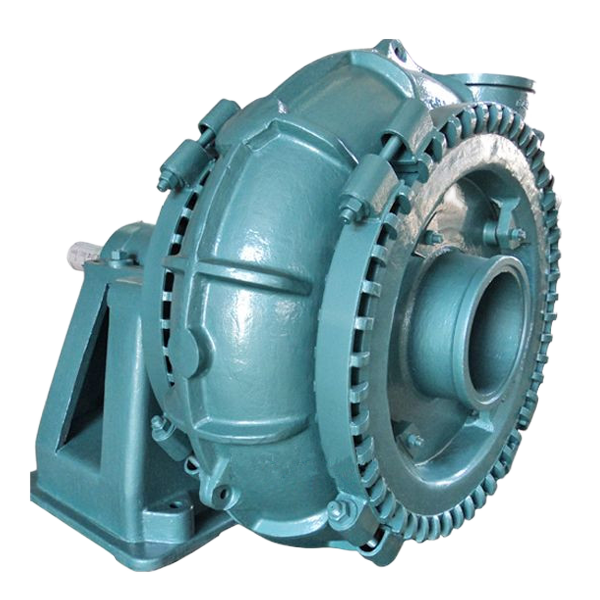

18/16TU-THR Rubber Lined Slurry Pump is standard heavy duty slurry pumps which designed for the continuous pumping of highly abrasive,high density slurries with minimal maintenance requirements,18/16 slurry pump maintains high efficiencies over the wear life of its components.This type of pump typically used in process plant transfers, wet waste processes, recycling-washing plants,sand plant duties, heavy minerals processing, mineral recovery and chemical process plant.

Design Features:

√ Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

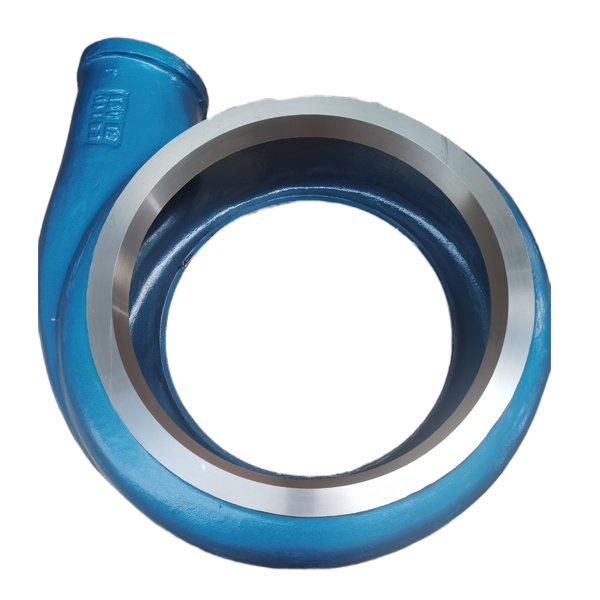

√ Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure moulded rubber.

√ Elastomer seal rings back all liner joints.

√ Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

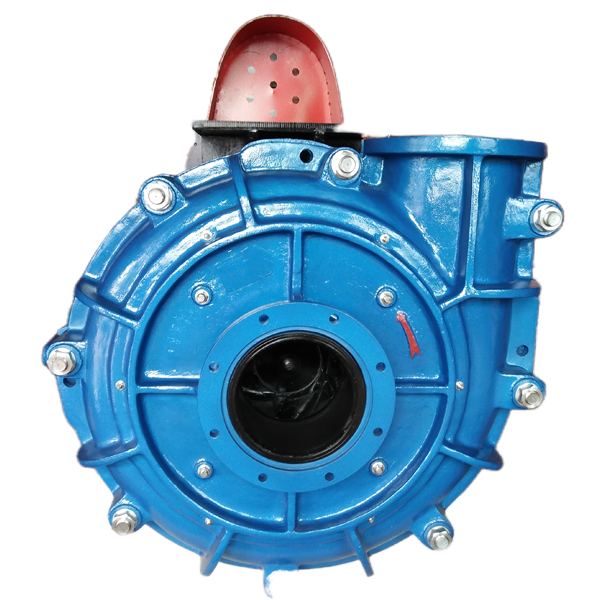

√ Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and moulded rubber impellers are completely interchangeable.

√ Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

√ Throatbush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

√ One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly.

√ An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

18/16 TU-THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

18/16TU-THR |

1200 |

Rubber |

Rubber |

2160-5040 |

8-66 |

200-500 |

80 |

4.5-9 |

5 |

THR Rubber Lined Slurry Pump Drive Module Design:

Grease Lubricated Bearing Assembly

The grease-lubricated bearing assembly houses a large-diameter shaft in its unique bearing cartridge designed specially for heavy-duty tasks. Due to its compact design, the bearing takes up little space while providing minimum vibration and deviation. Grease lubrication minimizes the possibility of oil leakage and little extra maintenance effort is needed. The rotor is easily adjustable. Users can install several rotors operating in series.

Horizontal Axially-Split Bearing Assembly

Lubricated by oil, the axially-split bearing assembly features a large-diameter shaft and a short cantilever. It delivers high rigidity, and is unlikely to deform or vibrate even when highly abrasive solids are encountered. The bearing is directly mounted inside the bearing support which can be split into 2 halves along its center line. This mounting method allows for ease of disassembly, inspection and adjustment of bearing. Water cooling system effectively cools down the hot bearing, greatly improving its use life.

Cartridge Type Oil-Lubricated Bearing Assembly

Spacious cartridge design allows for the installation of a large-diameter rotating shaft. Built specially to handle heavy-duty tasks, the metric size bearing is lubricated by thin oil. Users can install several bearings operating in series. Compact design and high reliability are 2 major benefits of this bearing for its end users.

Typical Application:

| • Mining

• Mineral processing • Construction • Chemical and Fertilization • Power generation |

• Phosphate matrix fertilization

• Pulp and paper • Waste sludge • Paper mill wastes and liquors • Precipitated CaCO3 |

• Plaster

• Bottom/fly ash, lime grinding • Dirty water • Pulp and paper • Oil and gas |

| • Waste water treatment

• Ball mill discharge • Rod mill discharge • SAG mill discharge • Fine tailing |

• Flotation

• Heavy media process • Minerals concentrate • Mineral sands • Coal-washing plant |

• Coarse sand

• Coarse tailing • Dredging • FGD • Wet crushers applications |

| • Wet scrubber systems

• Process chemical • Iron and Steel • Ni acid slurry • Fracking slurries |

• Clay and sand slurries

• Kaolin clay • Carbon slurry • Lime mud • Oil sands |

• Phosphoric acid |

Note:

18/16 TU THR rubber lined slurry pumps and spares are only interchangeable with Warman® 18/16 TU AHR rubber lined slurry pumps and spares.

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for High Quality for Ash Slurry Pumps - 18/16TU-THR Rubber Slurry Pump, Interchangeable anti-abrasive wet parts – Ruite Pump , The product will supply to all over the world, such as: Niger, luzern, Amman, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.