High reputation Ground Type Slurry Pump - 18x16TU-TG Gravel Pump China Supplier, best price – Ruite Pump

High reputation Ground Type Slurry Pump - 18x16TU-TG Gravel Pump China Supplier, best price – Ruite Pump Detail:

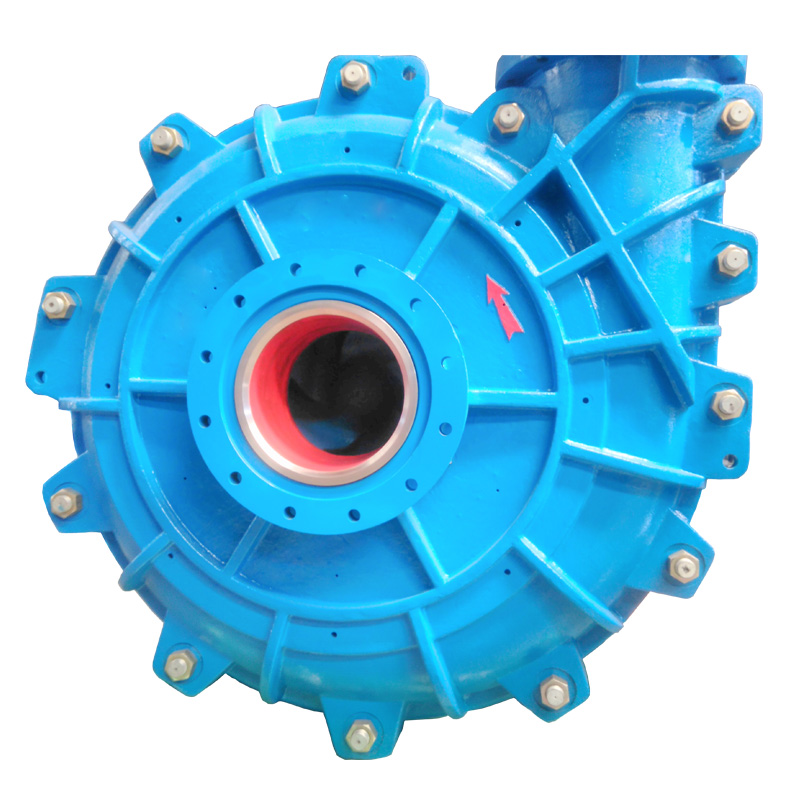

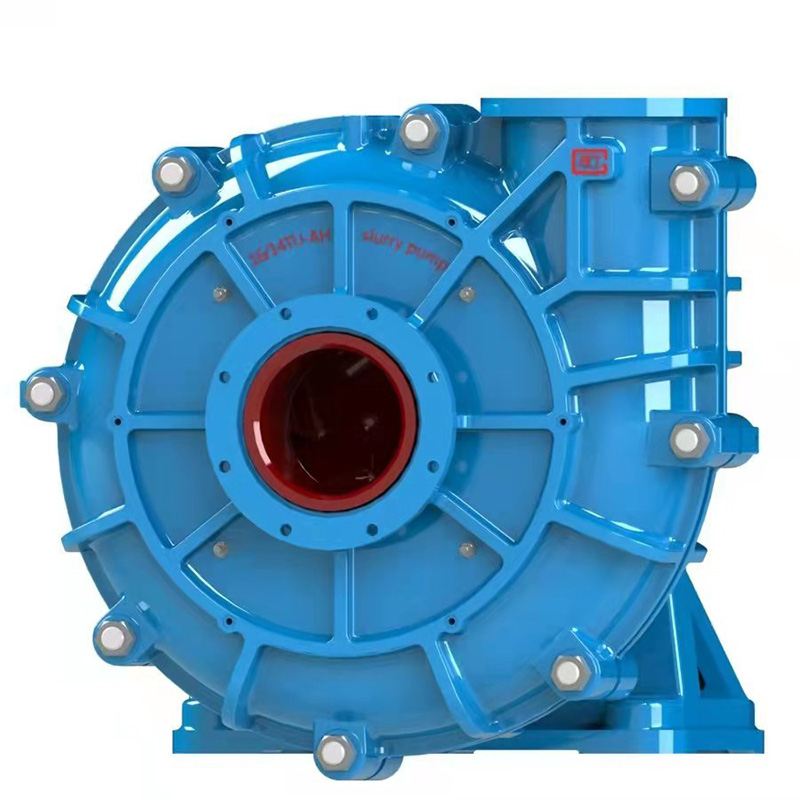

18x16TU-TG Gravel Pump is designed for continuous handling of the most difficult higher abrasive slurries, containing solids too large to be pumped by a standard slurry pump, The 18×16 gravel pump is widely used for Sand Excavation, Coal Washery, Power Plant, Mineral Processing Plants, Other industries.

Design Features:

• The unique segmented clamp ring on larger size units and solid on smaller pumps, facilitates casing rotation to any angle, reducing the need for costly high wearing bends. Minimal maintenance is required.

• Impeller expulsion vanes reduce gland pressure and intrusion of high concentrations of solids in the gland area. Efficiency is maintained by minimising suction side recirculation.

• Specially designed and shaped impeller vanes allow the handling of extraordinarily large particles. The unique casing design and sealing vanes prevent abrasive solids intrusion at the sealing faces.

• The large, robust casing has been designed to reduce internal velocities resulting in minimum efficiency loss and improved casing wear life. The casing is made up of three components to reduce maintenance time and costs associated with a one piece design.

• Ruite heavy-duty grease lubricated taper roller bearing assemblies are fitted as standard. A rigid large diameter shaft with reduced overhang minimises deflection and vibration under all conditions ensuring trouble free operation. Unusually high service factors enable the assembly to carry all radial and axial thrusts.

• A unique “-10” (dash 10) end cover assembly comprising of V-seals, double piston rings and an external flinger with grease lubricated labyrinths are standard with all Ruite pump.

18x16TU-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

18x16TU-TG |

1200 |

720-4320 |

12-48 |

250-500 |

72 |

3-6 |

1067 |

18x16TU-TG Gravel Pump Applications

The gravel pump is used for river course, reservoir desalting, coastal reclamation, stretching, deep-sea mining and tailing acquisition etc. Gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields.

Note:

18×16 TU-TG gravel pumps and spares are only interchangeable with Warman® 18×16 TU-G gravel pumps and spares.

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for High reputation Ground Type Slurry Pump - 18x16TU-TG Gravel Pump China Supplier, best price – Ruite Pump , The product will supply to all over the world, such as: New Orleans, Netherlands, Guinea, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

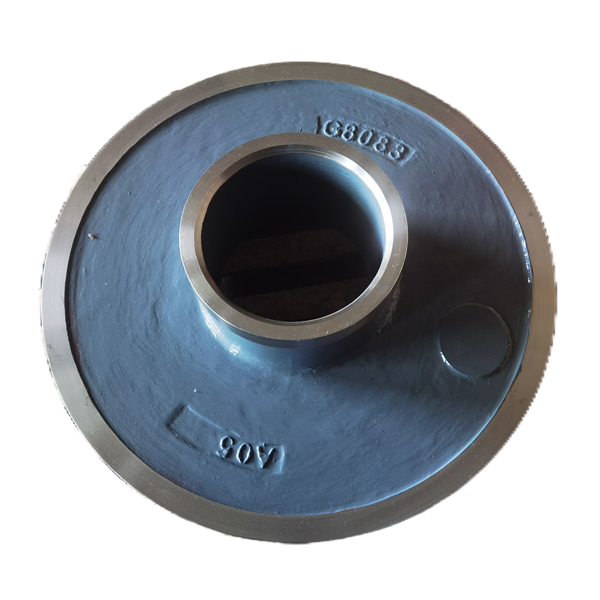

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!