New Delivery for Progressive Cavity Pump For Slurry - 200SV-TSP Vertical Slurry Pump – Ruite Pump

New Delivery for Progressive Cavity Pump For Slurry - 200SV-TSP Vertical Slurry Pump – Ruite Pump Detail:

200SV-TSP Vertical Slurry Pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer. Fully elastomer lined or hard metal fitted. No submerged bearings or packing. High capacity double suction design. Optional recessed impeller and suction agitator available.

Design Features

Less wear, less corrosion

Wetted components are available in a wide range of alloys and elastomers. Tobee selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance, and where larger particles or high density slurries are encountered.

• Abrasion resistant Ultrachrome® A05 alloy.

• Abrasion/corrosion-resistant Hyperchrome® A49 alloy.

• Corrosion-resistant stainless steels.

• Natural and synthetic elastomers.

No submerged bearing failures

The robust cantilever shaft avoids the need for lower submerged bearings which are often the source of premature bearing failure.

• Heavy duty roller bearings, above mounting plate.

• No submerged bearings.

• Labyrinth/flinger bearing protection.

• Rigid, large diameter shaft.

No shaft sealing problems

The vertical cantilever design requires no shaft seal.

No priming required.

The top and bottom inlet design is ideally suited for “snore” conditions.

Less risk of blocking

The screened inlets and large impeller passages reduce the risk of blockages.

Zero ancillary water costs

The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

200SV-TSP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

200SV-TSP(R) |

15-110 |

180-890 |

6.5-37 |

400-850 |

64 |

520 |

65 |

2800 |

200 SV SP Vertical Slurry Pumps Applications

• Mining

• Sump drainage

• Coal prep

• Mineral processing

• Mill sumps

• Tunnel

• Tailings

• Chemical slurries

• Ash handing

• Paper and Pulp

• Waste sludge

• Coarse sand

• Lime mud

• Phosphoric acid

• Sump Dredging

• Mill grinding

• Alumina Industry

• Power Plant

• Potash Fertilizer Plant

• Other industries

Note:

200 SV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 200 SV-SP vertical slurry pumps and spares.

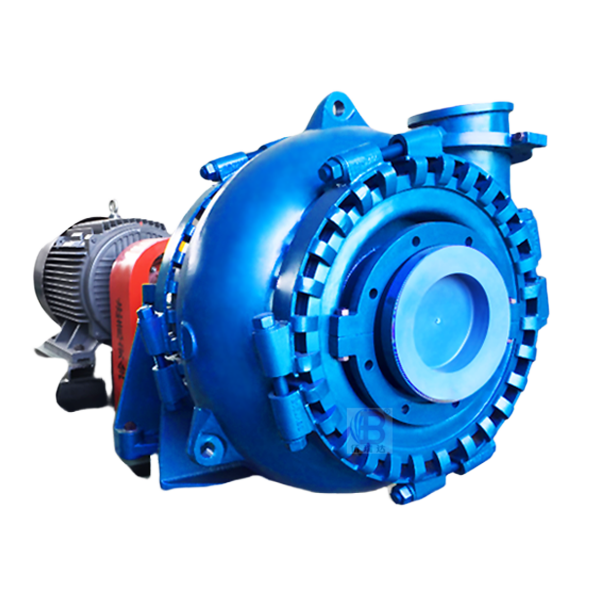

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for New Delivery for Progressive Cavity Pump For Slurry - 200SV-TSP Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: California, Comoros, Moldova, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.