Coal washing is to use the difference in physical and chemical properties of coal and impurities (gangue) for energy saving and emission reduction, and effectively separate coal and impurities by physical, chemical or microbial sorting methods. Coal preparation methods which commonly used in industrial production at present are jigging, heavy medium, flotation and so on.

According to the method of coal preparation and the amount of pump used, heavy medium coal preparation is the first choice. Heavy medium coal preparation refers to the use of particle density differences in coal preparation, and the medium is generally water and magnetite powder.

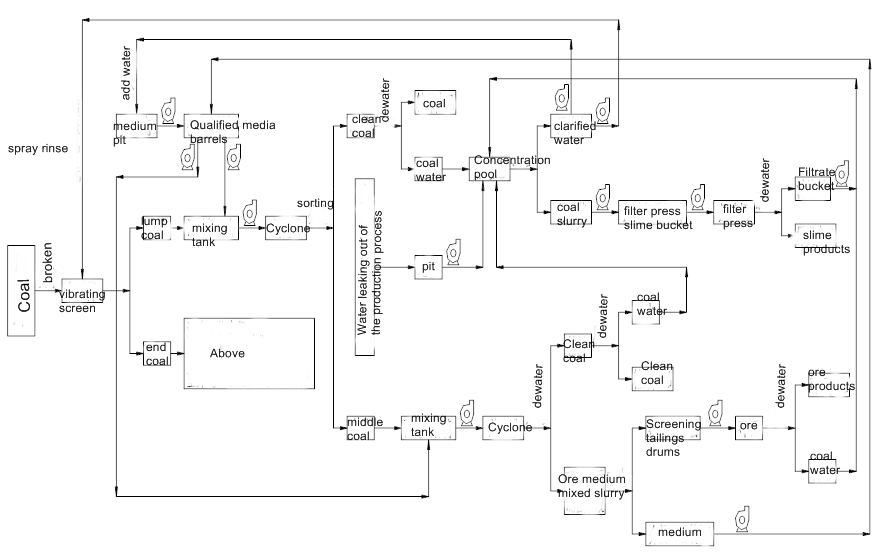

Coal preparation process and pump

Typical process of dense medium coal preparation

Process pumps (with an annual processing capacity of 10 million tons)

|

Equipment name |

Application |

Transfer medium density |

Performance(the total processing capacity, generally 2~3 systems) |

Service life |

| Main selection heavy medium cyclone feed pump | The mixture of coal and medium is fed into the cyclone for sorting | Density1.6,diameter: 50mm | Q=3000m3/h,H=35m | 1year |

| Coal cyclone feed pump | The mixture of under-sieve coal and medium is sent to the cyclone for separation | Density1.65 | Q=2500m3/h,H=25m | 1year |

| Qualified medium pump | Send qualified media into mixing tank | Density1.35 | Q=4000m3/h,H=20m | 1year |

| Diluted medium pump | Send the recovered medium by magnetic separation to the mixing tank | Density1.15 | Q=800m3/h,H=15m | 1~2year |

| Magnetic separation tailings pump | Send the gangue slurry after magnetic separation to sorting or dehydration equipment | Density1.05 | Q=900m3/h,H=30m | 3~5year |

| Sweep pump | The ditch coal slime water in the coal washing plant is sent to the concentration tank | Density1.2 | Q=100m3/h,H=25m | 2~3year |

| Addition pump | Replenish the media for the mixing tank | Density1.35 | Q=100m3/h,H=20m | 1year |

| Concentrator underflow pump | The concentrated coal slurry is sent to the dehydration equipment | Density1.65 | Q=280m3/h,H=30m | 1year |

| clarification pump | Send the clarified water from the concentration tank to the system for reuse | Density1.15 | Q=2500m3/h,H=50m | 2~3year |

| Re-select heavy medium pump | The mixture of re-selected coal and medium is sent to the cyclone for sorting | Density1.65 | Q=2500m3/h,H=35m | 1year |

| Re-select the media pump | Send the qualified media into the re-selection mixing tank | Density1.65 | Q=2000m3/h,H=35m | 1year |

| Filtrate pump | Send the filter press filtrate to the concentration tank | Density1.1 | Q=200m3/h,H=20m | 2~3year |

| Filter press feed pump | Send the coal slime slurry to the filter press for dehydration | Density1.2 | Q=300m3/h,H=80m | 1year |

| Circulating pump | Density1.05 | Q=3500m3/h,H=50m | 3~5year |

Demand for a series of products in the coal washing industry

1. The structural shaft seal adopts the impeller seal, and the flange adopts the metric flange; Overflow part service life more than 1 year

2. Divided into three categories according to process and station

1) Dense medium pump and medium pump: strong abrasion and larger particles, the maximum particle size is 50mm, and the minimum overflow particle size of the pump is designed to be 100mm;

2) Transporting slime water: In addition to the heavy medium pump, medium pump, and filter press feed pump, it mainly transports slime water (including pumps for jigging coal preparation and flotation process), and is designed according to light abrasive conditions;

3) Filter press feed pump: similar without overload performance;

Circulating water pump: circulating water supply, little solid content, Density 1~1.1, generally less than 1.05;

3. Product demand plan

1) The installation size of the base is designed as an adjustable structure, which is convenient for users who use other companies’ products to replace the products of our factory without changing the foundation.

2) Two materials for the overflow parts of the pump; one material is for heavy abrasive mining and the other is for light abrasive conditions, to reduce the target costs.

3) Heavy-abrasive industrial and mining (dense medium pump, medium pump) pump can be a double-shell structure.

4) The pump casing of light-abrasive industrial and mining (conveying coal slime water) can be a single-shell structure

Ruite pump company has a professional technical team, can help you choose the suitable pump for your project.

Welcome your inquiries

Whatsapp: +8619933139867

Post time: Aug-08-2022