Rapid Delivery for Slurry Pump For Mining - AHF Horizontal Froth Pumps, Chinese manufacturers – Ruite Pump

Rapid Delivery for Slurry Pump For Mining - AHF Horizontal Froth Pumps, Chinese manufacturers – Ruite Pump Detail:

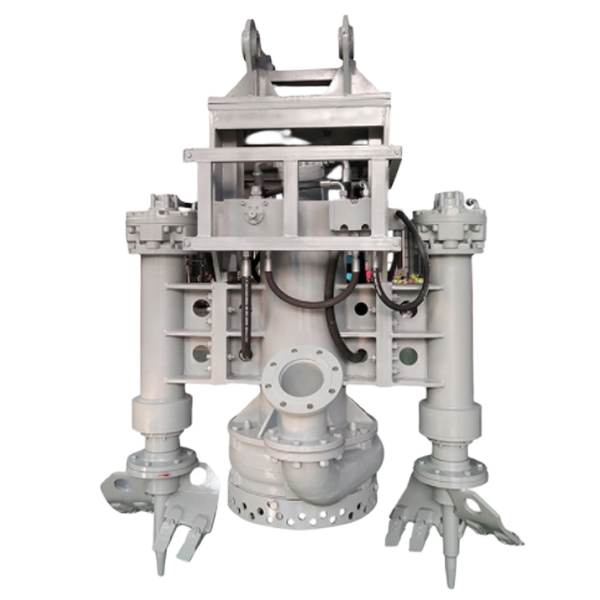

AHF Horizontal Froth Pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth.

Design Features:

•Based on the AH or L series slurry pumps

•Existing AH or L series slurry pumps can be converted to AHF/MF/LF horizontal froth pumps with only a few modifications

•Inducer blade impeller for positive froth feed

•Enlarged high efficiency slurry throatbush to maximize the inlet size and reduce NPSH required

•Standard AH or L slurry pump mounting and flange center lines

•Available in 2”through 22”froth pump discharge sizes

Application:

The mining industry is a primary example where pumping operations can be plagued by froth and high viscosity problems.In the liberation of minerals from ore,the minerals are often floated through the use of strong flotation agents.Tough bubbles carry the copper,molybdenum or iron tails to be recovered and further processed.These tough bubbles create havoc with many slurry pumps,often leading to the selection of overly large and inefficient pumps.horizontal froth pumps are small and efficient.The inducer impeller and oversized inlet very effectively enable the froth or viscous slurries to get into the impeller allowing the pump to transport it to the next destination.Low power costs,reliable operation,minimal surging,and feed tank overflow make horizontal froth pumps user friendly.

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Rapid Delivery for Slurry Pump For Mining - AHF Horizontal Froth Pumps, Chinese manufacturers – Ruite Pump , The product will supply to all over the world, such as: Belize, Jersey, Palestine, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!