100% Original Factory Sand Extractor Pump - 10/8S-TG Gravel Pump, wide application, Highly efficient and stable – Ruite Pump

100% Original Factory Sand Extractor Pump - 10/8S-TG Gravel Pump, wide application, Highly efficient and stable – Ruite Pump Detail:

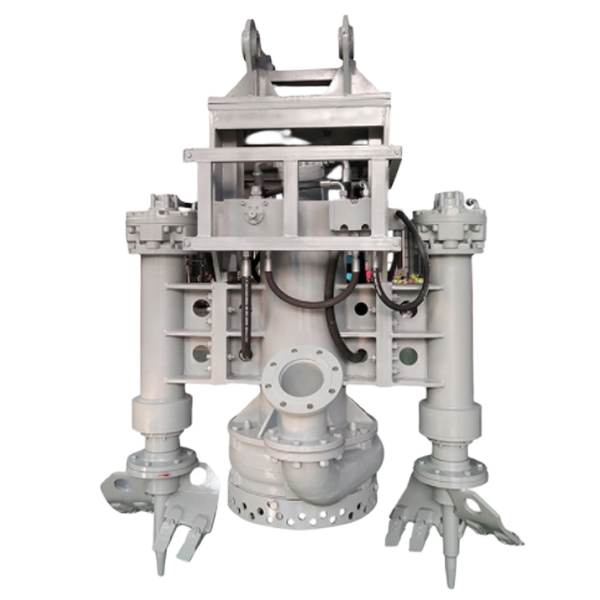

10x8S-TG Gravel Pumps are the most comprehensive range of centrifugal gravel sand pumps for use in mining, chemical and general industry applications. The horizontal sand gravel pumps are designed for heavy duty applications such as mining, power sector,dredging river,and tailings as well as specialty applications, which are used for continuous pumping of high abrasive, high density sand and gravels.

10x8S-TG Gravel Pump Wear Parts Design

Impeller: Front and back shroud expulsion vanes reduce gland pressure and intrusion of high concentrations of solids in the gland area. Efficiency is maintained by minimizing suction side recirculation. Specially designed and shaped impeller vanes allow the handling of extraordinarily large particles. The unique casing design and sealing vanes prevent abrasive solids intrusion at the sealing faces.

Casing: Robust casing has been designed to reduce internal velocities resulting in minimum efficiency loss and improved casing wear life. The casing is made up of three components to reduce maintenance time and costs associated with a one piece design.

Expeller (Centrifugal Seal): no external sealing water required where applicable.

Stuffing Box: flushed gland sealing with braided packing and a lantern ring.

Bearing Assembly: heavy-duty grease lubricated taper roller bearing assemblies are fitted as standard. A rigid large diameter shaft with reduced overhang minimises deflection and vibration under all conditions ensuring trouble free operation. Unusually high service factors enable the assembly to carry all radial and axial thrusts.

10x8S-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

10x8S-TG |

560 |

216-936 |

8-52 |

500-1000 |

65 |

3-7.5 |

533 |

10x8S-TG Gravel Pumps Applications

TG/TGH heavy-duty sand & gravel pump design typically caters for high head high volume duties, The Gravel pumps are best suited to Sand & Gravels, Dredging, Cutter Suction Dredger, Sand Excavation, Coal Washing, Tunnels, Power Plant, Mineral Processing Plants, Higher head cyclone feed or Long distance pipeline duties and Other industries.

NOTE:

10×8 S-TG gravel pumps and spares are only interchangeable with Warman® 10×8 S-G gravel pumps and spares.

Product detail pictures:

Related Product Guide:

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for 100% Original Factory Sand Extractor Pump - 10/8S-TG Gravel Pump, wide application, Highly efficient and stable – Ruite Pump , The product will supply to all over the world, such as: Portugal, Algeria, UAE, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.