Best-Selling Slurry Pump Vertical - 6/4D-AHR Rubber Slurry Pump, warman rubber slurry pump – Ruite Pump

Best-Selling Slurry Pump Vertical - 6/4D-AHR Rubber Slurry Pump, warman rubber slurry pump – Ruite Pump Detail:

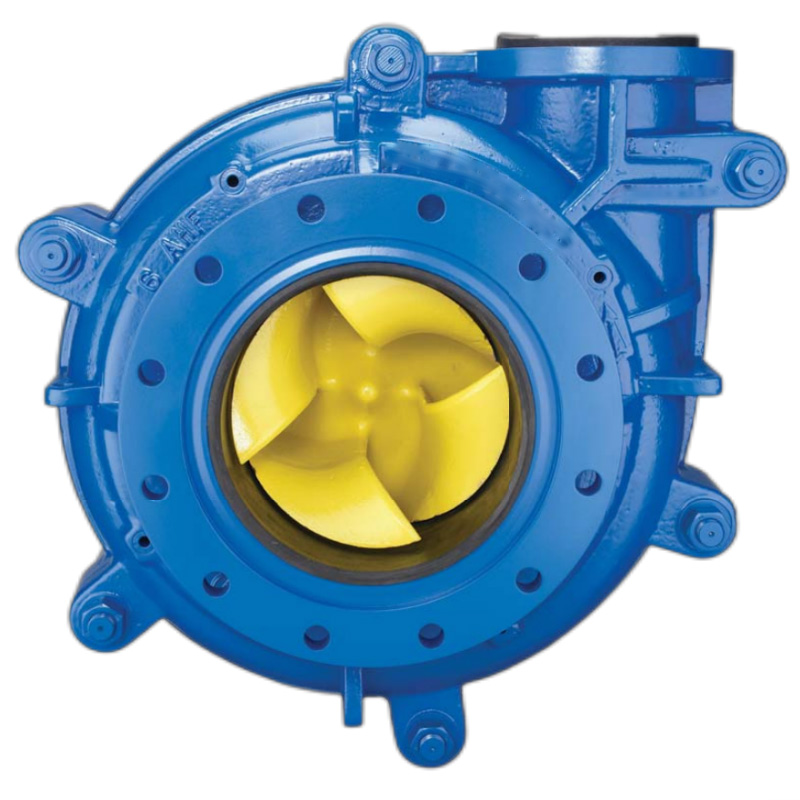

6/4D-THR Rubber Lined Slurry Pump is similar to 6x4D-AH Metal Lined Slurry Pump in structure.The main difference between AH and THR is the material of wet parts,which are natural rubber,synthetic rubber or other wear-resistant rubbers.The Rubber Lined Slurry Pumps are more suitable in delivering strong corrosive or abrasive slurries of small particle size without sharp edges.

Advantages

√Optimized structure is suitable for heavy-duty tasks,ensuring serviceability and longevity.

√The double-casing design of our heavy duty rubber lined slurry pump allows for axial split.Made of ductile iron,the slurry pump casing is able to withstand major pressure produced within the pumping chamber.Rubber liners are made of wear resistant rubber materials,and do not stick to the outer casing for ease of maintenance and replacement.

√The slurry pump body is fixed to the pump base or mounting base by several bolts.Users can adjust the clearance between impeller and suction liner easily from underneath the bearing support,or bearing pedestal.

√Packing gland seal,mechanical seal and expeller seal are available to prevent slurry leakage during pumping operation

6/4 D THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max.Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff.η (%) |

NPSH (m) |

|||

|

6/4D-THR |

60 |

Rubber |

Rubber |

144-324 |

12-45 |

800-1350 |

65 |

3-5 |

5 |

Rubber Lined Slurry Pumps Applications:

Mining&Mineral Processing

The slow running speeds of the Tobee heavy duty rubber lined slurry pump,together with the comprehensive choice of abrasion resistant alloys and elastomers,provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Chemical Process

The interchangeability of alloy and elastomer components in the same pump casing,together with a wide range of mechanical seals,make the Tobee heavy duty rubber lined slurry pump the most flexible choice for the chemical plant environment.

Sand&Gravel

Designed for easy and simple strip down and re-assembly,the Tobee heavy duty rubber lined slurry pump minimises downtime,making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the Tobee heavy duty rubber lined slurry pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

Flue Gas Desulphurisation

The new generation of specially formulated abrasion and corrosion resistant alloys,together with the very latest elastomer technology,positions Tobee Pumps firmly as a major supplier of pumps to the FGD industry.

Oil&Gas Exploration

Over a number of years we have developed the proven design of the Tobee heavy duty rubber lined slurry pump ranges to suit the specific demands of offshore applications.We can now offer the most reliable top side solution to erosive wear.

Industrial Applications

Wherever abrasive solids are causing premature failure of pumps,the Tobee heavy duty rubber lined slurry pump range has the right combination of performance,wear life and reliability to bring the customer the lowest cost of ownership.

Note:

6/4 D THR rubber lined slurry pumps and parts are only interchangeable with Warman®6/4 D THR rubber lined slurry pumps and parts.

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Best-Selling Slurry Pump Vertical - 6/4D-AHR Rubber Slurry Pump, warman rubber slurry pump – Ruite Pump , The product will supply to all over the world, such as: Boston, Czech, Atlanta, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!