Factory For Sand Dredge Pump - TSPR Rubber Lined Vertical Slurry Pump – Ruite Pump

Factory For Sand Dredge Pump - TSPR Rubber Lined Vertical Slurry Pump – Ruite Pump Detail:

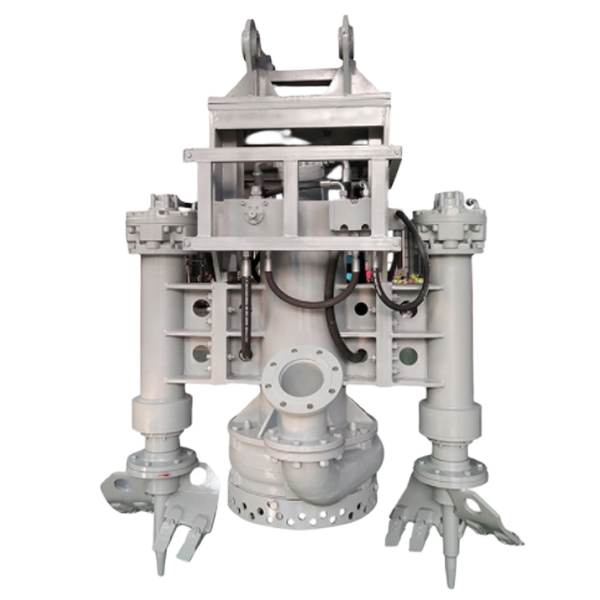

TSPR Rubber Lined Vertical Slurry Pumps are available in various standard lengths to suit common sump depths, for very deep sumps or where high shaft speeds limit the length of the pump, a suction extension pipe can be fitted to the bottom inlet to extend the depth of the pump by up to 2 meters. Pumping is maintained even when the top inlet is not submerged, thus enabling the level of liquid to be lowered right down to the bottom inlet or the bottom of any suction extension pipe. The wet parts of TSPR vertical sump pump is interchangeable with the SP series hard metal lined heavy duty sump pumps.

Design Features

√ Bearing Assembly – The bearings, shaft and housing are generously proportioned to avoid problems associated with the operation of cantilevered shafts in the first critical speed zones.

The assembly is grease lubricated and sealed by labyrinths; the upper is grease purged and the lower protected by a special flinger. The upper or drive end bearing is a parallel roller type whilst the lower bearing is a double taper roller with preset end float. This high performance bearing arrangement and robust shaft eliminates the need for a lower submerged bearing.

√ Column Assembly – Completely fabricated from mild steel. The TSPR model is elastomer covered.

√ Casing – Has a simple bolt-on attachment to the base of the column. It is manufactured from a wear resistant alloy for the TSP and from moulded elastomer for the TSPR.

√ Impeller – Double suction impellers (top and bottom entry) induce low axial bearing loads and have heavy deep vanes for maximum wear resistance and for handling large solids. Wear resistant alloys, polyurethane and moulded elastomer impellers are interchangeable. The impeller is adjusted axially within the casting during assembly by external shims under the bearing housing feet. No further adjustment is necessary.

√ Upper Strainer – Drop-in metal mesh; snap-on elastomer or polyurethane for TSP and TSPR pumps. Strainers fit in column openings.

√ Lower Strainer – Bolted metal or polyurethane for TSP; moulded snap-on elastomer for TSPR.

√ Discharge Pipe – Metal for TSP; elastomer covered for TSPR. All wetted metal parts are completely rust protected.

√ Submerged Bearings – None

√ Agitation – An external agitator TSPRay connection arrangement can be fitted to the pump as an option. Alternatively, a mechanical agitator is fitted to an extended shaft protruding from the impeller eye.

√ Materials – Pumps can be manufactured in abrasive and corrosive resistant materials.

TSPR Rubber Lined Vertical Slurry Pumps Performance Parameters

|

Model |

Max.Power P (kw) |

Clear Water Performance |

Impeller dia. (mm) |

||||

|

Capacity Q |

Head H (m) |

Speed n (r/min) |

Max. Eff. (%) |

||||

|

m3/h |

l/s |

||||||

|

40PV-TSPR |

15 |

17.28-39.6 |

4.8-11 |

4–26 |

1000-2200 |

40 |

188 |

|

65QV-TSPR |

30 |

22.5-105 |

6.25-29.15 |

5.5-30.5 |

700-1500 |

51 |

280 |

|

100RV-TSPR |

75 |

64.8-285 |

18-79.2 |

7.5-36 |

600-1200 |

62 |

370 |

|

150SV-TSPR |

110 |

108-479.16 |

30-133.1 |

8.5-40 |

500-1000 |

52 |

450 |

|

200SV-TSPR |

110 |

189-891 |

152.5-247.5 |

6.5-37 |

400-850 |

64 |

520 |

|

250TV-TSPR |

200 |

261-1089 |

72.5-302.5 |

7.5-33.5 |

400-750 |

60 |

575 |

|

300TV-TSPR |

200 |

288-1267 |

80-352 |

6.5-33 |

350-700 |

50 |

610 |

TSPR Rubber Lined Vertical Slurry Pumps Applications

The TSPR and SP designs, manufactured in popular metric sizes, provide a simple, yet rugged range of sump pumps specially developed for: Abrasive and/or corrosive slurries, Large particle size, High slurry densities, Continuous or “snore” operations,Heavy duties demanding cantilevered shafts in minerals processing, coal preparation, chemical processing, effluent handling, sand and gravel, and almost every other tank, pit or hole-in-the-ground slurry handling situation.

NOTE:

TSPR rubber lined vertical slurry pumps and spares are only interchangeable with Warman® SPR rubber lined vertical slurry pumps and spares.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Factory For Sand Dredge Pump - TSPR Rubber Lined Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Sydney, Switzerland, South Africa, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,