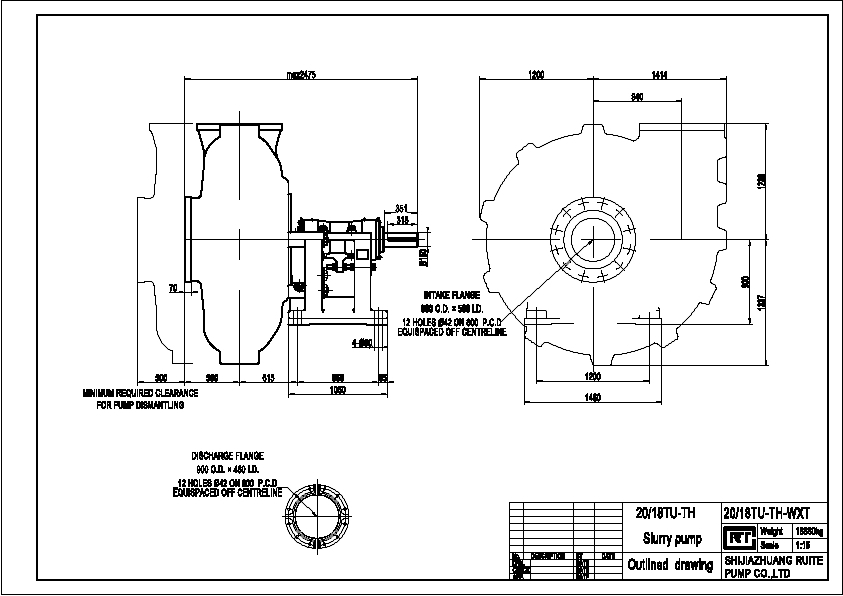

OEM/ODM China 2 Dredge Pump - 20/18 TU-TH Slurry Pump, high quality&good price – Ruite Pump

OEM/ODM China 2 Dredge Pump - 20/18 TU-TH Slurry Pump, high quality&good price – Ruite Pump Detail:

Description

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

Types

Submersible

Submersible slurry pumps are placed at the bottom of a tank, lagoon, pond, or another water-filled environment, and suction solids and liquids right at the pump itself. The materials are taken in at the intake and passed through a hose connected to the discharge valve.

Flooded Suction

The flooded suction slurry pump is connected to a tank or hopper and uses gravity to move slurry and liquid from the enclosure.

Shijiazhuang Ruite Pump Co.Ltd

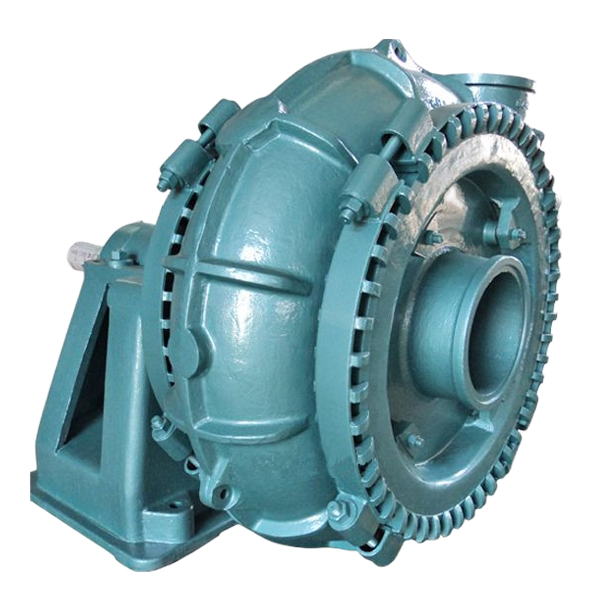

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

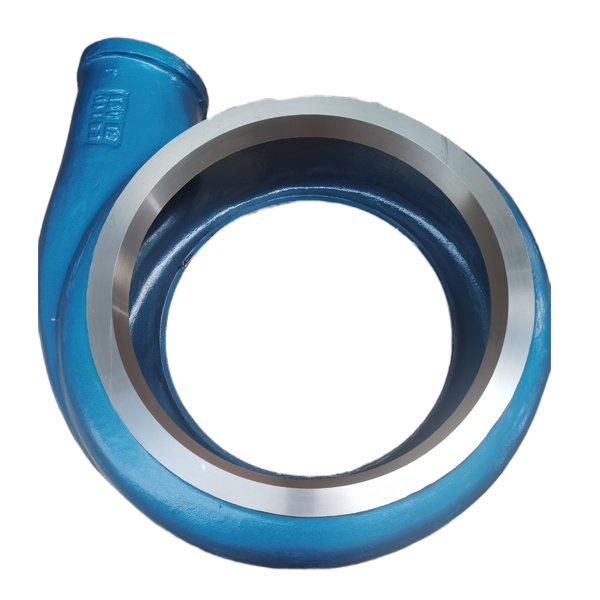

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

The Process Flow

Texture Profile

Advantages of Ruite Pump Features

1. Modular design, easy to maintain,low spare cost due to high standardization;

2. Wide options of impellers of standard 5vanes , 4vanes high efficiency and 2vanes non-clogging,

3.27% Chrome allov hard metal. thick rubber and polvurethane pump lining are available and can be replaced with each other

4. Standard ductile iron pump body, can withstand higher working pressure,

5.Famous brand bearing components can improve reliability, prolong bearing life and reduce lubrication cost

6.Reliable shaft seal, packing seal, expeller seal, or mechanical seal are available.

7.Multi purpose design reduces inventorv requirements and interchangeability:

8.Drive types:Different connection methods (ZVZ.DC.CV.CRZ) with motor for selection, satisfy the reguirements on different installation condition and different capacity & head.

9.The discharge direction of the pump can be oriented to any 8 positions based on different installation condition.

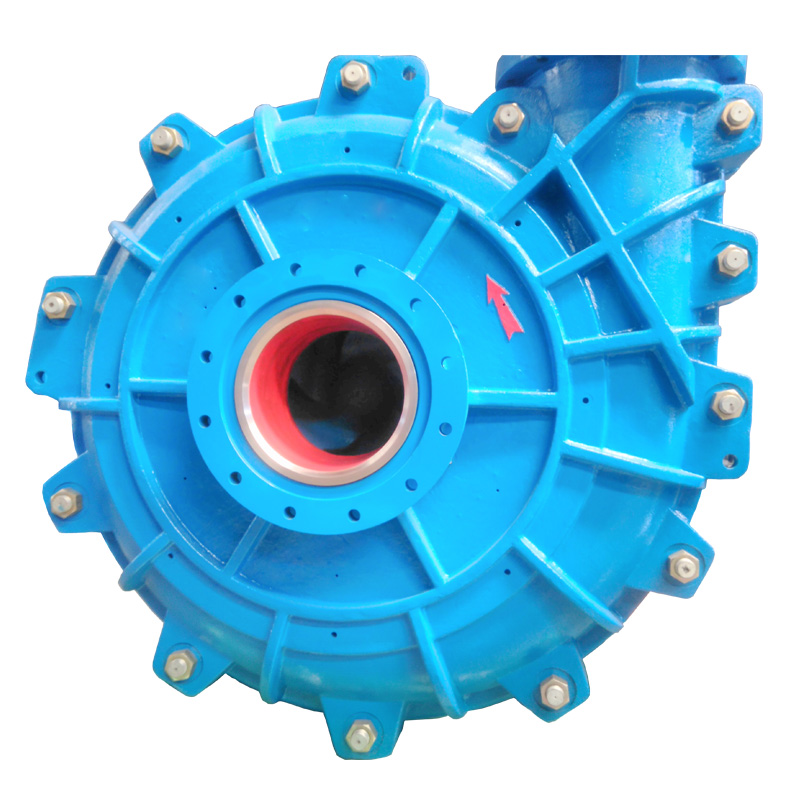

More Details

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for OEM/ODM China 2 Dredge Pump - 20/18 TU-TH Slurry Pump, high quality&good price – Ruite Pump , The product will supply to all over the world, such as: Argentina, Bangkok, Netherlands, Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

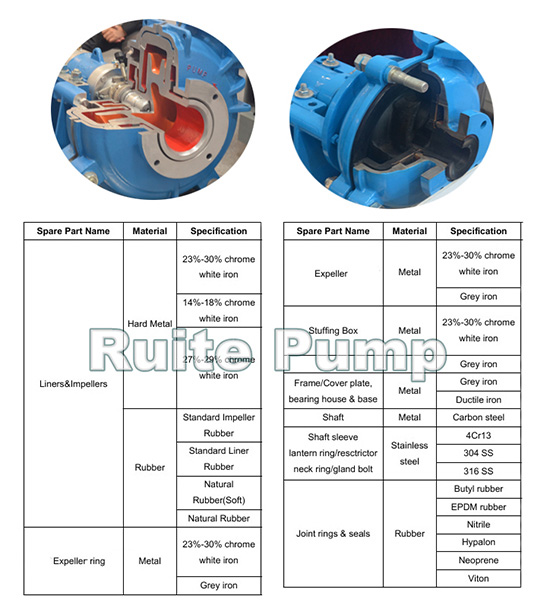

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.