Professional Design Horizontal Centrifugal Slurry Pump - High efficiency, wear-resisting TQ submersible slurry pump – Ruite Pump

Professional Design Horizontal Centrifugal Slurry Pump - High efficiency, wear-resisting TQ submersible slurry pump – Ruite Pump Detail:

Description

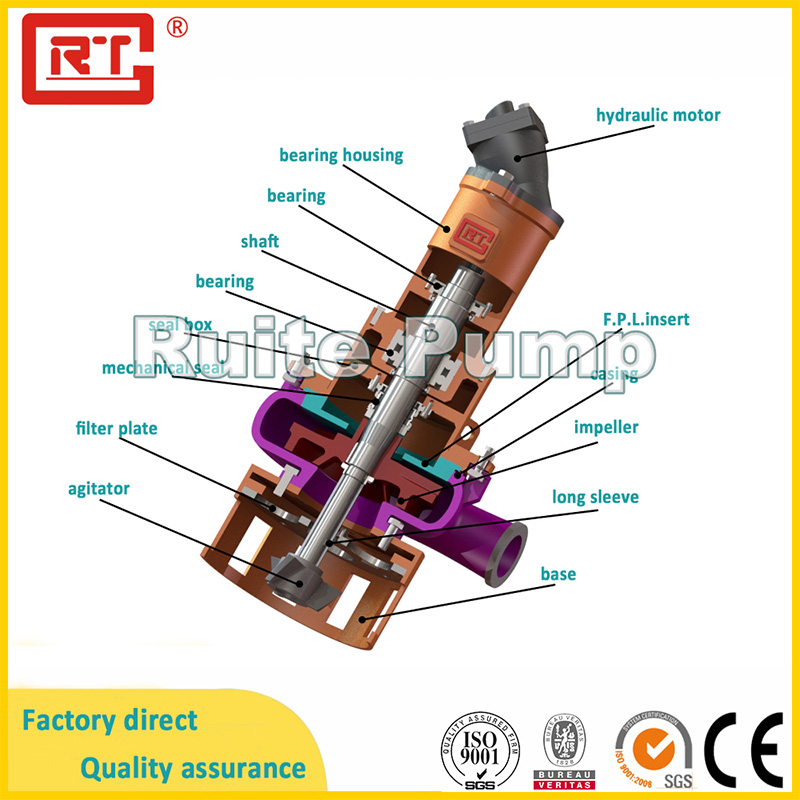

RT TQ Submersible Slurry Pumps are heavy duty agitator submersible slurry pumps, dredge Pumps, sand Pumps, and sludge Pumps in the Industry, capable of handling slurry, sand, gravel, solids and all kinds of sludge in diverse applications related to the dredging, construction, oil and mining industry as well as marine, energy, and industrial sectors. TQ Submersible Slurry Pumps deliver massive solids production at very low operational costs. Hydroman offers the highest head submersible, largest capacity, heavy duty slurry pumps available on the market.

Design Features

√ HIGH-EFFICIENCY HIGH CHROME REVERSIBLE AGITATOR

Doubles the life of the agitator. The excavating action is created by the hardened high chrome agitator blades. They create a current that lifts settled sediments conveying them to the suction of the impeller which delivers a continuous flow of solids to the pump discharge.

√ LOW OPERATING RPM

Low operating RPM promotes low wear rates and extended component life. When compared to other pumps of similar capacity Hydroman has a lower operating speed.

√ OVERSIZED MOTORS

All Hydroman electric motors are oversized and are designed for slurries up to 1.6 SG. A Hydraulic drive version is also available providing higher output. RT hydraulic augers THY can be attached directly to the pump creating a self-contained excavating system for hard compacted sand where a mechanical excavator would otherwise be required.

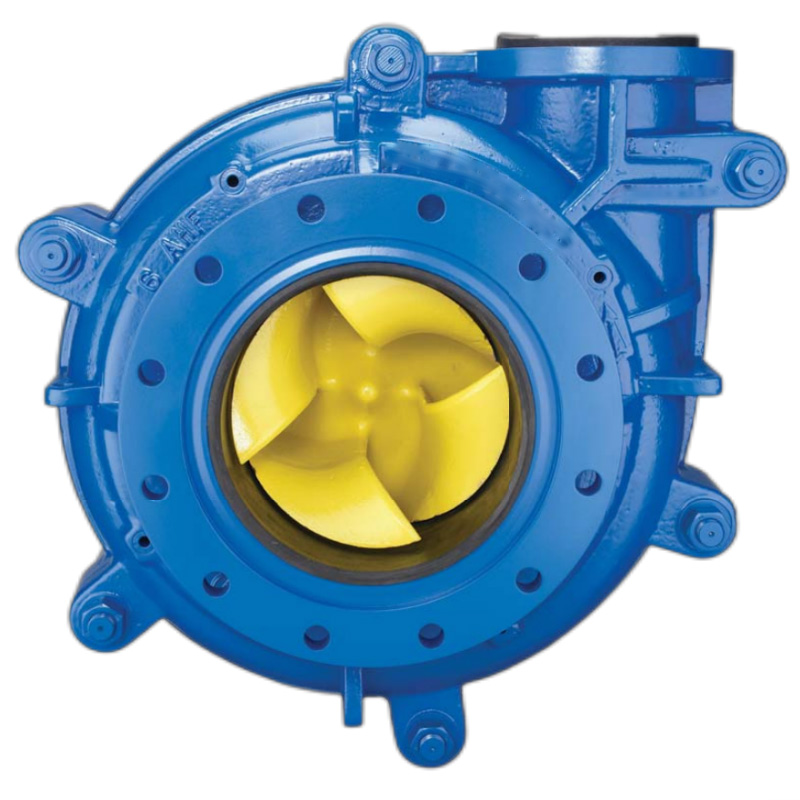

√ ROBUST CONSTRUCTION

Long life and reliability are guaranteed by robust heavy-duty construction. Extra strong wear components provide extended life between spare paRT changes. All paRT s that are exposed or subjected to abrasive wear are manufactured in GS 500 or Hi Chrome alloys.

√ THRUST BEARINGS

All Hydroman models have been designed with dual thrust bearings to reduce vibration and counter thrust loads in both directions.

√ SOLIDS HANDLING CHARACTERISTICS

RT slurry pump paRT s have been specially designed and shaped to provide outstanding performance, providing superb solids handling capabilities but with reduced wear and solid size up to 5 inch (120 mm).

√ STRUCTURAL CHARACTERISTICS

Adjustable Hi-Chrome suction side Wear Plate maintains maximum performance for extended periods by a simple adjustment of the gap between the wear plate and the impeller.

Service Bolt: These bolts allow easy pump disassembly, a built-in service tool.

Replaceable wear paRT s: casings, impellers, wear plates all can be replaced independently

Lube oil inspection poRT s: A wide-angle poRT outside the pump ensures easy inspection of shaft seal oil levels as well as providing easy access for oil replacement.

√ LARGEST RANGE OF SUBMERSIBLE PUMPS

From 5 HP to 400 HP and discharge diameters from 3″ to 16″

√ HIGH HEAD PUMP IN THE MARKET

Handling slurries of up to 1.6 SG.

√ OPTIONAL MECHANICAL SEAL, LIP SEAL OR HYBRID SEAL SYSTEMS

According to the application.

√ CUTTERS HEADS AVAILABLE

Both Hydraulic and Electric, for hard compacted soil.

√ OPTIONS FOR SEVERAL APPLICATIONS

High chrome casing, Cooling Jacket, Anti corrosion package, Anti abrasion package, Lower membrane protection, Cutter knife, Temperature and moisture sensors, custom frames to fix the pump in the boom of excavator machines.

RT TQ Submersible Slurry Pumps Applications:

Industry: Pumping industrial waste, extraction of slag, forge scale, cal-cines, sludge, setting sludge, petroleum and tar residues, Thermal Power plants – Ash pits, Construction and public works, IneRT wash sludge, Marble dust, All types of effluent with solids in suspension, Sewage, De-watering etc

Dredging, Sand & Gravel: Sand extraction and transpoRT , Sand and gravel mining, Dredging harbors and marinas, PoRT maintenance, Dredging of canals and harbors, Clean-up of rivers, lakes and lagoons, Dam dredging, Beach reclamation, Heavy soils etc

Mining: Mining and tailings reclamation, Clean-up of setting tanks, Extraction of coal, minerals and sand etc.

Offshore: Underwater work, Ecological recovery, Clean-up of locks, Emptying of caissons and bulkheads, Barge transfer etc

RT TQ Submersible Slurry Pumps Performance Parameters:

|

No. |

Model |

Size (mm) |

Capacity Q (m3/h) |

Head H (m) |

Power P (kw) |

Eff. η (%) |

Speed n (r/min) |

Max. paRT icles (mm) |

Weight (kg) |

|

1 |

50TQ10-20-3 |

50 |

10 |

20 |

3 |

37 |

1460 |

8 |

110 |

|

2 |

50TQ15-18-3 |

50 |

15 |

18 |

3 |

46 |

1460 |

8 |

110 |

|

3 |

50TQ20-15-3 |

50 |

20 |

15 |

3 |

52 |

1460 |

8 |

110 |

|

4 |

50TQ25-12-3 |

50 |

25 |

12 |

3 |

58 |

1460 |

8 |

110 |

|

5 |

65TQ30-12-3 |

65 |

30 |

12 |

3 |

60 |

1460 |

8 |

110 |

|

6 |

65TQ35-10-3 |

65 |

35 |

10 |

3 |

64 |

1460 |

8 |

110 |

|

7 |

65TQ40-8-3 |

65 |

40 |

8 |

3 |

66 |

1460 |

8 |

110 |

|

8 |

50TQ15-22-4 |

50 |

15 |

22 |

4 |

43 |

1460 |

10 |

113 |

|

9 |

50TQ18-20-4 |

50 |

18 |

20 |

4 |

46 |

1460 |

10 |

113 |

|

10 |

50TQ20-18-4 |

50 |

20 |

18 |

4 |

50 |

1460 |

10 |

113 |

|

11 |

50TQ25-20-4 |

50 |

25 |

20 |

4 |

52 |

1460 |

10 |

113 |

|

12 |

65TQ30-16-4 |

65 |

30 |

16 |

4 |

52 |

1460 |

10 |

113 |

|

13 |

65TQ35-15-4 |

65 |

35 |

15 |

4 |

60 |

1460 |

10 |

113 |

|

14 |

65TQ40-12-4 |

65 |

40 |

12 |

4 |

63 |

1460 |

10 |

113 |

|

15 |

65TQ45-10-4 |

65 |

45 |

10 |

4 |

66 |

1460 |

10 |

113 |

|

16 |

80TQ20-30-5.5 |

80 |

20 |

30 |

5.5 |

42 |

1460 |

13 |

205 |

|

17 |

80TQ30-20-5.5 |

80 |

30 |

20 |

5.5 |

54 |

1460 |

13 |

205 |

|

18 |

80TQ45-15-5.5 |

80 |

45 |

15 |

5.5 |

41 |

1460 |

13 |

205 |

|

19 |

80TQ15-20-5.5 |

80 |

15 |

20 |

5.5 |

33 |

1460 |

13 |

205 |

|

20 |

80TQ50-10-5.5 |

80 |

50 |

10 |

5.5 |

44 |

1460 |

13 |

205 |

|

21 |

80TQ15-20-7.5 |

80 |

15 |

20 |

7.5 |

34 |

1460 |

13 |

210 |

|

22 |

80TQ20-25-7.5 |

80 |

20 |

25 |

7.5 |

35 |

1460 |

13 |

210 |

|

23 |

80TQ25-20-7.5 |

80 |

25 |

20 |

7.5 |

36 |

1460 |

13 |

210 |

|

24 |

80TQ25-30-7.5 |

80 |

25 |

30 |

7.5 |

36 |

1460 |

13 |

210 |

|

25 |

80TQ30-30-7.5 |

80 |

30 |

30 |

7.5 |

37 |

1460 |

13 |

210 |

|

26 |

80TQ32-20-7.5 |

80 |

32 |

20 |

7.5 |

37 |

1460 |

13 |

210 |

|

27 |

80TQ45-15-7.5 |

80 |

45 |

15 |

7.5 |

41 |

1460 |

13 |

210 |

|

28 |

100TQ100-10-7.5 |

100 |

100 |

10 |

7.5 |

48 |

1460 |

21 |

220 |

|

29 |

80TQ25-40-11 |

80 |

25 |

40 |

11 |

36 |

1460 |

13 |

300 |

|

30 |

80TQ40-25-11 |

80 |

40 |

25 |

11 |

38 |

1460 |

13 |

240 |

|

31 |

80TQ50-21-11 |

80 |

50 |

21 |

11 |

40 |

1460 |

13 |

240 |

|

32 |

80TQ50-26-11 |

80 |

50 |

26 |

11 |

40 |

1460 |

13 |

240 |

|

33 |

80TQ70-20-11 |

80 |

70 |

20 |

11 |

43 |

1460 |

13 |

240 |

|

34 |

100TQ100-18-11 |

100 |

100 |

18 |

11 |

48 |

1460 |

21 |

240 |

|

35 |

80TQ25-40-15 |

80 |

25 |

40 |

15 |

37 |

1460 |

13 |

330 |

|

36 |

80TQ50-26-15 |

80 |

50 |

26 |

15 |

40 |

1460 |

13 |

260 |

|

37 |

80TQ50-28-15 |

80 |

50 |

28 |

15 |

40 |

1460 |

13 |

260 |

|

38 |

100TQ60-30-15 |

100 |

60 |

30 |

15 |

41 |

1460 |

13 |

265 |

|

39 |

80TQ70-24-15 |

80 |

70 |

24 |

15 |

42 |

1460 |

13 |

260 |

|

40 |

100TQ75-25-15 |

100 |

75 |

25 |

15 |

43 |

1460 |

13 |

260 |

|

41 |

100TQ100-18-15 |

100 |

100 |

18 |

15 |

49 |

1460 |

21 |

270 |

|

42 |

100TQ150-15-15 |

100 |

150 |

15 |

15 |

51 |

1460 |

21 |

270 |

|

43 |

150TQ150-18-18.5 |

150 |

150 |

18 |

18.5 |

49 |

980 |

32 |

550 |

|

44 |

150TQ200-12-18.5 |

150 |

200 |

12 |

18.5 |

53 |

980 |

45 |

550 |

|

45 |

150TQ150-22-22 |

150 |

150 |

22 |

22 |

47 |

980 |

32 |

600 |

|

46 |

150TQ200-15-22 |

150 |

200 |

15 |

22 |

50 |

980 |

45 |

600 |

|

47 |

150TQ60-46-30 |

150 |

60 |

46 |

30 |

41 |

980 |

14 |

550 |

|

48 |

150TQ70-38-30 |

150 |

70 |

38 |

30 |

42 |

980 |

21 |

710 |

|

49 |

150TQ100-35-30 |

150 |

100 |

35 |

30 |

44 |

980 |

21 |

710 |

|

50 |

150TQ108-30-30 |

150 |

108 |

30 |

30 |

44 |

980 |

21 |

710 |

|

51 |

150TQ150-30-30 |

150 |

150 |

30 |

30 |

46 |

980 |

21 |

710 |

|

52 |

150TQ150-35-30 |

150 |

150 |

35 |

30 |

46 |

980 |

21 |

710 |

|

53 |

150TQ200-20-30 |

150 |

200 |

20 |

30 |

52 |

980 |

21 |

710 |

|

54 |

150TQ240-20-30 |

150 |

240 |

20 |

30 |

55 |

980 |

21 |

710 |

|

55 |

200TQ300-15-30 |

200 |

300 |

15 |

30 |

56 |

980 |

28 |

700 |

|

56 |

150TQ100-50-37 |

150 |

100 |

50 |

37 |

44 |

980 |

21 |

850 |

|

57 |

200TQ300-20-37 |

200 |

300 |

20 |

37 |

56 |

980 |

28 |

775 |

|

58 |

200TQ400-15-37 |

200 |

400 |

15 |

37 |

58 |

980 |

28 |

775 |

|

59 |

150TQ150-35-45 |

150 |

150 |

35 |

45 |

47 |

980 |

36 |

1000 |

|

60 |

150TQ200-30-45 |

150 |

200 |

30 |

45 |

49 |

980 |

36 |

1110 |

|

61 |

200TQ500-15-45 |

200 |

500 |

15 |

45 |

59 |

980 |

46 |

1100 |

|

62 |

150TQ150-45-55 |

150 |

150 |

45 |

55 |

46 |

980 |

21 |

1140 |

|

63 |

150TQ250-35-55 |

150 |

250 |

35 |

55 |

51 |

980 |

36 |

1140 |

|

64 |

250TQ600-15-55 |

250 |

600 |

15 |

55 |

60 |

980 |

46 |

1220 |

|

65 |

150TQ200-45-75 |

150 |

200 |

45 |

75 |

49 |

980 |

21 |

1540 |

|

66 |

150TQ200-50-75 |

150 |

200 |

50 |

75 |

48 |

980 |

14 |

1550 |

|

67 |

200TQ350-35-75 |

200 |

350 |

35 |

75 |

53 |

980 |

28 |

1550 |

|

68 |

200TQ400-25-75 |

200 |

400 |

25 |

75 |

58 |

980 |

25 |

1550 |

|

69 |

200TQ500-20-75 |

200 |

500 |

20 |

75 |

59 |

980 |

25 |

1550 |

|

70 |

150TQ200-60-90 |

150 |

200 |

60 |

90 |

48 |

980 |

14 |

1550 |

|

71 |

200TQ400-40-90 |

200 |

400 |

40 |

90 |

54 |

980 |

28 |

1550 |

|

72 |

200TQ500-25-90 |

200 |

500 |

25 |

90 |

60 |

980 |

25 |

1550 |

|

73 |

200TQ400-50-110 |

200 |

400 |

50 |

110 |

53 |

980 |

28 |

1970 |

|

74 |

250TQ600-30-110 |

250 |

600 |

30 |

110 |

61 |

980 |

28 |

1970 |

|

75 |

300TQ780-26-110 |

300 |

780 |

26 |

110 |

62 |

980 |

50 |

1970 |

|

76 |

300TQ1000-18-110 |

300 |

1000 |

18 |

110 |

64 |

980 |

50 |

1970 |

|

77 |

200TQ400-60-132 |

200 |

400 |

60 |

132 |

53 |

980 |

28 |

2000 |

|

78 |

200TQ500-45-132 |

200 |

500 |

45 |

132 |

56 |

980 |

28 |

2000 |

|

79 |

200TQ500-55-132 |

200 |

500 |

55 |

132 |

55 |

980 |

28 |

2000 |

|

80 |

300TQ800-35-132 |

300 |

800 |

35 |

132 |

63 |

980 |

42 |

2000 |

|

81 |

300TQ1000-22-132 |

300 |

1000 |

22 |

132 |

64 |

980 |

50 |

2000 |

|

82 |

200TQ650-52-160 |

200 |

650 |

52 |

160 |

58 |

980 |

28 |

2650 |

|

83 |

300TQ780-50-185 |

300 |

780 |

50 |

185 |

60 |

980 |

38 |

3330 |

|

84 |

250TQ600-55-200 |

250 |

600 |

55 |

200 |

62 |

980 |

28 |

4080 |

|

85 |

300TQ800-55-220 |

300 |

800 |

55 |

220 |

60 |

980 |

38 |

3400 |

|

86 |

350TQ1250-35-220 |

350 |

1250 |

35 |

220 |

65 |

980 |

45 |

3400 |

|

87 |

350TQ1750-30-250 |

350 |

1750 |

30 |

250 |

70 |

980 |

55 |

3750 |

|

88 |

350TQ1500-35-250 |

350 |

1500 |

35 |

250 |

70 |

980 |

50 |

3750 |

|

89 |

350TQ1750-40-315 |

350 |

1750 |

40 |

315 |

70 |

980 |

55 |

4200 |

|

90 |

400TQ2000-35-315 |

400 |

2000 |

35 |

315 |

72 |

980 |

60 |

3800 |

Product detail pictures:

Related Product Guide:

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for Professional Design Horizontal Centrifugal Slurry Pump - High efficiency, wear-resisting TQ submersible slurry pump – Ruite Pump , The product will supply to all over the world, such as: Luxemburg, Kazakhstan, Pakistan, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.