Wholesale Discount Sand Suction Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump

Wholesale Discount Sand Suction Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump Detail:

100RV-TSP Vertical Slurry Pump is designed for handling abrasive and corrosive liquids and slurries, while submerged in sumps or pits. Suited for applications requiring greater reliability and durability than conventional vertical process pumps can offer. It is mainly used for pumping the slurries with high abrasive, strong corrosion and high concentration liquids contain suspended solid particles.

Design Features

• Bearing Assembly - The bearings, shaft and housing are generously proportioned to avoid problems associated with the operation of cantilevered shafts in the first critical speed zones.

The assembly is grease lubricated and sealed by labyrinths; the upper is grease purged and the lower protected by a special flinger. The upper or drive end bearing is a parallel roller type whilst the lower bearing is a double taper roller with preset end float. This high performance bearing arrangement and robust shaft eliminates the need for a lower submerged bearing.

• Column Assembly - Completely fabricated from mild steel. The SPR model is elastomer covered.

• Casing - Has a simple bolt-on attachment to the base of the column. It is manufactured from a wear resistant alloy for the SP and from moulded elastomer for the SPR.

• Impeller - Double suction impellers (top and bottom entry) induce low axial bearing loads and have heavy deep vanes for maximum wear resistance and for handling large solids. Wear resistant alloys, polyurethane and moulded elastomer impellers are interchangeable. The impeller is adjusted axially within the casting during assembly by external shims under the bearing housing feet. No further adjustment is necessary.

• Upper Strainer - Drop-in metal mesh, snap-on elastomer or polyurethane for SP and SPR pumps. Strainers fit in column openings.

• Lower Strainer - Bolted metal or polyurethane for SP, moulded snap-on elastomer for SPR.

• Discharge Pipe - Metal for SP, elastomer covered for SPR. All wetted metal parts are completely rust protected.

• Submerged Bearings - None

• Agitation - An external agitator spray connection arrangement can be fitted to the pump as an option. Alternatively, a mechanical agitator is fitted to an extended shaft protruding from the impeller eye.

• Materials - Pumps can be manufactured in abrasive and corrosive resistant materials.

100 RV-TSP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

100RV-TSP(R) |

5.5-75 |

40-289 |

5-36 |

500-1200 |

62 |

370 |

32 |

920 |

100 RV-TSP Vertical Spindle Pumps are available in a wide range of popular sizes to suit most pumping applications:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Sand and gravel

and almost every other tank, pit or hole-in-theground slurry handling situation.

Note:

100 RV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 100 RV-SP vertical slurry pumps and spares.

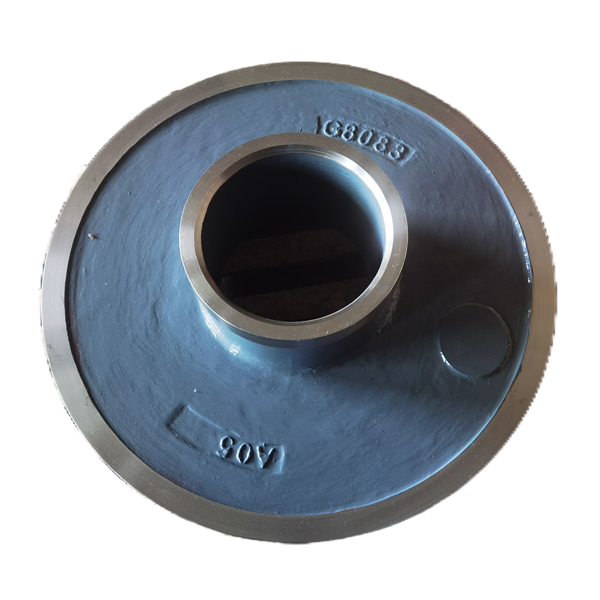

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Wholesale Discount Sand Suction Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Malaysia, Mauritania, Lesotho, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.