CE Certificate Mill Spillage pump with polyurethane material wearing parts Impeller D3147U01 U02

Our improvement depends around the sophisticated gear, outstanding talents and repeatedly strengthened technology forces for CE Certificate Mill Spillage pump with polyurethane material wearing parts Impeller D3147U01 U02, When you are interested in any of our merchandise or would want to go over a custom made get, remember to feel totally free to contact us.

Our improvement depends around the sophisticated gear, outstanding talents and repeatedly strengthened technology forces for , We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

Description

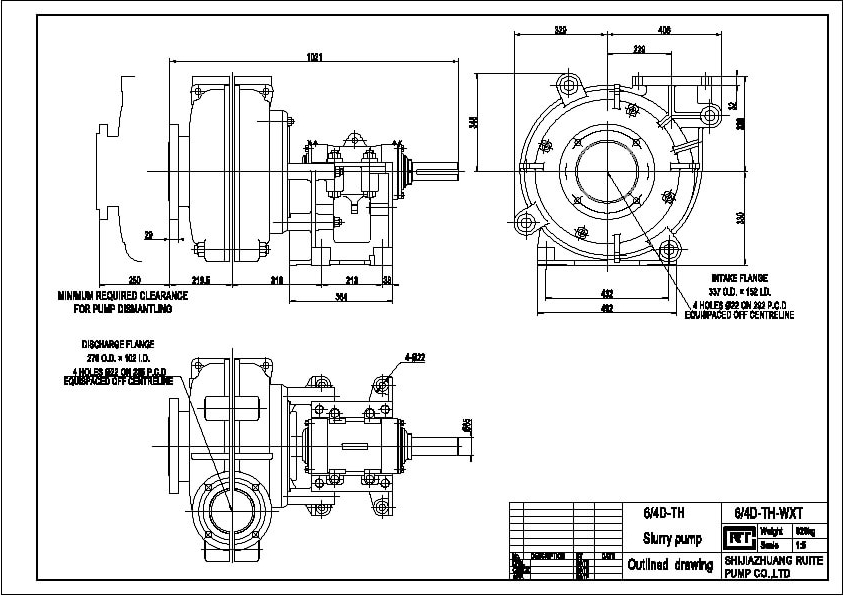

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

Marketing Words

1、Ruite is a leading Chinese pump manufacturer and devoted to offering professional slurry pump solutions for you. We have successfully undertaken many projects in over 40 countries. Innovative R&D department and state-of-art technology are the basis of Excellence high quality products. Scientific model selection and slurry transporting solution helps to reduce your purchase and maintenance cost. Above all, all-around services will save you a lot of effort and it will be a enjoyable experience.

2、Ruite production line includes four major procedures strictly supervised by our quality control personnel, including foundry, machining, assembling and testing.

Shijiazhuang Ruite Pump Co.Ltd

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

About RT

RT Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

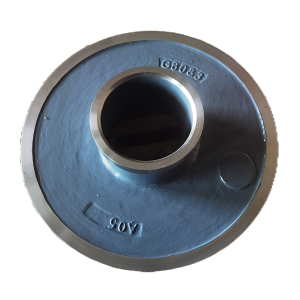

At present, Ruite has the new material MC01, MC01 spares part service life is 1.5-2 times than A05 material.

Our production ability 1200ton per month,The largest wear-resistant casting weighs can up to 12 ton. Welcome to visit.thank you

The Process Flow

Texture Profile

More Details

Our improvement depends around the sophisticated gear, outstanding talents and repeatedly strengthened technology forces for CE Certificate Mill Spillage pump with polyurethane material wearing parts Impeller D3147U01 U02, When you are interested in any of our merchandise or would want to go over a custom made get, remember to feel totally free to contact us.

Our improvement depends around the sophisticated gear, outstanding talents and repeatedly strengthened technology forces for CE Certificate Mill Spillage pump with polyurethane material wearing parts Impeller D3147U01 U02, When you are interested in any of our merchandise or would want to go over a custom made get, remember to feel totally free to contact us.

CE Certificate , We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

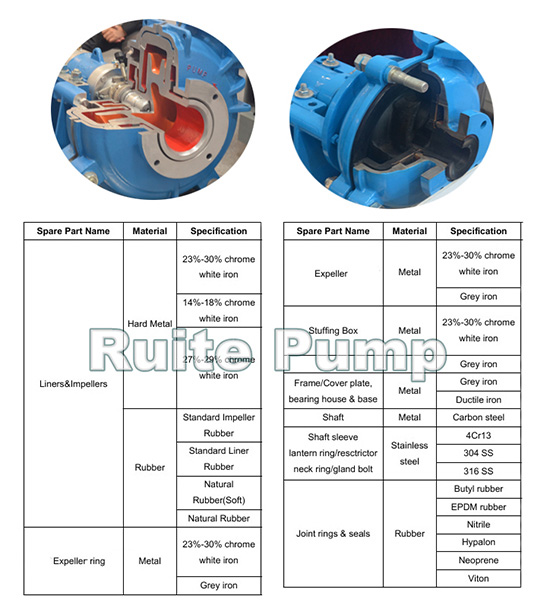

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |