Hot sale Through-Put Dredge Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump

Hot sale Through-Put Dredge Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump Detail:

100RV-TSP Vertical Slurry Pump is designed for handling abrasive and corrosive liquids and slurries, while submerged in sumps or pits. Suited for applications requiring greater reliability and durability than conventional vertical process pumps can offer. It is mainly used for pumping the slurries with high abrasive, strong corrosion and high concentration liquids contain suspended solid particles, The wear parts are made of high chromium for the TSP series and are rubber lined for the TSPR series.

All slurries share five essential characteristics:

More abrasive than pure liquids.

Thicker in consistency than pure liquids.

May contain a high number of solids (measured as a percentage of the total volume).

The solid particles usually settle out of the slurry’s precipitate relatively quickly when not in motion (depending on the particle size).

Slurries require more energy to move than do pure liquids.

Design Features

• Bearing Assembly - The bearings, shaft and housing are generously proportioned to avoid problems associated with the operation of cantilevered shafts in the first critical speed zones.

The assembly is grease lubricated and sealed by labyrinths; the upper is grease purged and the lower protected by a special flinger. The upper or drive end bearing is a parallel roller type whilst the lower bearing is a double taper roller with preset end float. This high performance bearing arrangement and robust shaft eliminates the need for a lower submerged bearing.

• Column Assembly - Completely fabricated from mild steel. The SPR model is elastomer covered.

• Casing - Has a simple bolt-on attachment to the base of the column. It is manufactured from a wear resistant alloy for the SP and from moulded elastomer for the SPR.

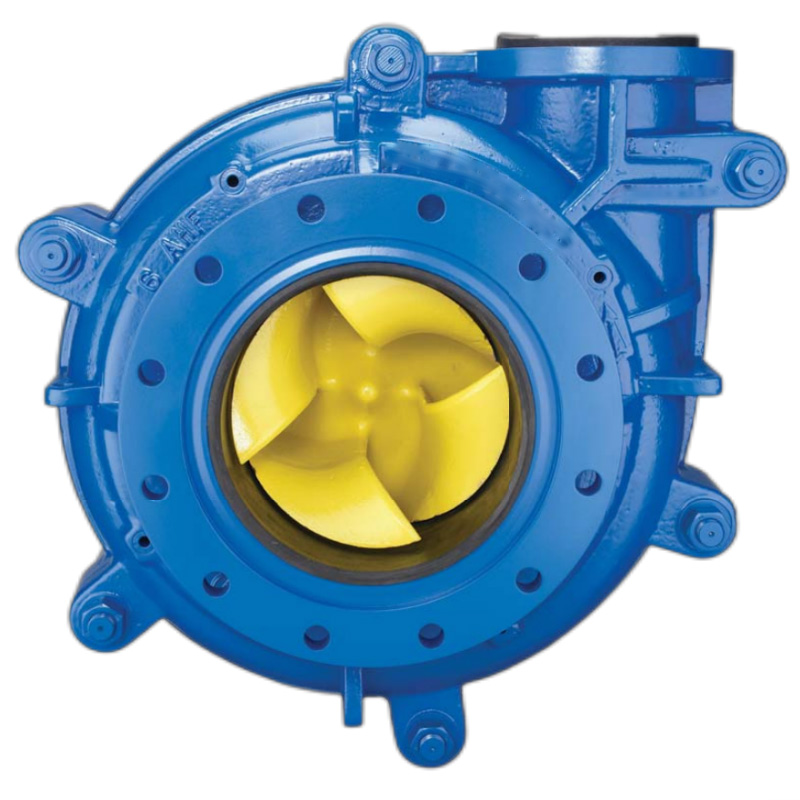

• Impeller - Double suction impellers (top and bottom entry) induce low axial bearing loads and have heavy deep vanes for maximum wear resistance and for handling large solids. Wear resistant alloys, polyurethane and moulded elastomer impellers are interchangeable. The impeller is adjusted axially within the casting during assembly by external shims under the bearing housing feet. No further adjustment is necessary.

Ruite Pump Industry Co., Ltd. is devoting to offering the best slurry pump solution around the world. With years of accumulation and development, we have formed a complete system of slurry pump production, design, selection, application and maintenance. Our products are widely used in mining, metallurgy, coal washery, power plant, sewage water treatment, dredging, and chemical and petroleum industries. Thanks to the trust and recognition of our clients from over 60 countries, we are becoming one of the most important slurry pump suppliers in China.

100 RV-TSP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

100RV-TSP(R) |

5.5-75 |

40-289 |

5-36 |

500-1200 |

62 |

370 |

32 |

920 |

100 RV-TSP Vertical Spindle Pumps are available in a wide range of popular sizes to suit most pumping applications:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Sand and gravel

and almost every other tank, pit or hole-in-theground slurry handling situation.

Note:

100 RV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 100 RV-SP vertical slurry pumps and spares.

♦ Pre-sale data calculation & model selection: experienced engineers provide scientific solutions, which could greatly lower customer comprehensive input cost.

♦ On-purchase service: professional sales team.

♦ After-sales service: Training: free training about methods of pump application and maintenance.

♦ On-site Guidance: installation guidance and possible problem elimination.

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Hot sale Through-Put Dredge Pump - 100RV-TSP Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Florence, Paraguay, Brunei, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.