Newly Arrival China Heavy Duty and Cost Effective Submersible Dredge Pump Designed for Dredging Sand, Pumping Slurry Silt and Mud or Mining Gravel

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Newly Arrival China Heavy Duty and Cost Effective Submersible Dredge Pump Designed for Dredging Sand, Pumping Slurry Silt and Mud or Mining Gravel, The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for China CE Certificate Dredging Pump, Dredge Vertical Pump, Our company sticks to the principle of “high quality, reasonable price and timely delivery”. We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent merchandise and services. Welcome to join us!

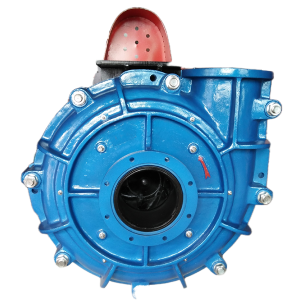

6/4E-THR Rubber Lined Slurry Pump is cantilevered,horizontal,centrifugal with double casing slurry pump.They are designed for the handling of highly abrasive,high-density slurries.The wet parts of 6×4 slurry pumps are made of natural rubber,which could be replaceable wear-resistant parts.The discharge side can be oriented to any of the eight different positions.The shaft seals may adopt packing gland seal,expeller seal and mechanical seal.

Design Features:

√Bearing assembly–A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life.Only four through bolts are required to hold the cartridge type housing in the frame.

√Liners–Easily replaceable liners are bolted,not glued,to the casing for positive attachment and ease of maintenance.Hard metal liners are completely interchangeable with pressure molded rubber.Elastomer seal rings back all liner joints.

√Casing–Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

√Impeller–Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.Hard metal and molded rubber impellers are completely interchangeable.Cast in impeller threads require no inserts or nuts.High efficiency and high head designs are also available.

√Throatbush–Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

√One-piece frame–A very robust one-piece frame cradles the cartridge type bearing and shaft assembly.An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

6/4 E THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

6/4E-AHR |

120 |

Rubber |

Rubber |

144-324 |

12-45 |

800-1350 |

65 |

3-5 |

5 |

Rubber Lined Slurry Pumps Applications:

√Iron Ore Dressing Plant

√Copper Concentration Plant

√Gold Mine Concentration Plant

√Molybdenum Concentration Plant

√Potash Fertilizer Plant

√Other Mineral Processing Plants

√Alumina Industry

√Coal Washery

√Power Plant

√Sand Excavation

√Building Material Industry

√Chemical Industry

√Other industries

Note:

6/4 E THR rubber lined slurry pumps and parts are only interchangeable with Warman®6/4 E THR rubber lined slurry pumps and parts.To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Newly Arrival China Heavy Duty and Cost Effective Submersible Dredge Pump Designed for Dredging Sand, Pumping Slurry Silt and Mud or Mining Gravel, The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

Newly Arrival China CE Certificate Dredging Pump, Dredge Vertical Pump, Our company sticks to the principle of “high quality, reasonable price and timely delivery”. We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent merchandise and services. Welcome to join us!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

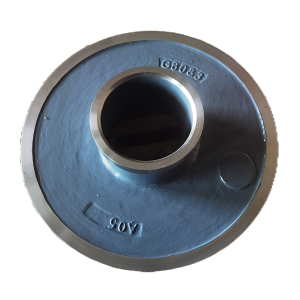

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |