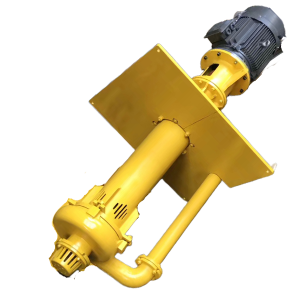

OEM Customized China Agricultural Irrigation Diesel Engine Water Pump High Capacity Double Suction Pump Mine Dewatering Pump

Each member from our significant effectiveness gross sales team values customers’ wants and enterprise communication for OEM Customized China Agricultural Irrigation Diesel Engine Water Pump High Capacity Double Suction Pump Mine Dewatering Pump, We generally concertrating on creating new creative item to meet request from our clients everywhere in the world. Be a part of us and let’s make driving safer and funnier alongside one another!

Each member from our significant effectiveness gross sales team values customers’ wants and enterprise communication for China Double Suction Pump, High Pressure Pump, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

3/2C-AHR Rubber Lined Slurry Pump is designed for the continuous pumping of high abrasive,high density slurries with minimal maintenance requirements.It will maintain high efficiency over the wear life of its components.The rubber lined slurry pumps feature casings which are radially split into two halves.Minimum casing bolts reduce maintenance and minimise downtime.

Design Features:

√High-efficiency design with very low power costs

√Proven hydraulics for slurry service,Extended parts wear life Thick bolt-in liners

√Positive assembly in casing for extended life

√Large liners reinforced with a fiberglass shell Resist liner collapse under adverse conditions

√Large-diameter closed impeller Lower speeds and extended wear life

√Replaceable suction wear plate available on 6 inch(150 mm)and larger rubber slurry pumps,Provides reduced downtime and lower replacement cost

√Axially adjustable bearing assembly Maintains peak operating efficiency and life

√Short,rigid shaft and heavy-duty bearings Low deflections and reliable service

√Packed gland option or mechanical seal Standard,low or no dilution arrangements

√Precision-machined cast iron frame Sturdy,vibration-free support

√Five discharge positions available Suitable for most piping arrangements

3/2 C THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

3/2C-AHR |

30 |

Rubber |

Rubber |

36-75.6 |

13-39 |

1300-2100 |

55 |

2-4 |

5 |

Rubber Lined Slurry Pumps Sealing Arrangement:

Packing Seal

As one of the most commonly used seals for rotating shafts,the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing.This kind of seal is suitable for use under all pumping conditions.In situations where corrosive solids or high temperature might be encountered,Teflon or aramid fiber is used as the packing material for the gland.For high abrasion conditions,a ceramic shaft sleeve is available.

Centrifugal Seal-Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage.Together with the gland seal or lip seal which is used as the shut-down seal,this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site,or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

MA series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement.Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction.Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Rubber Lined Slurry Pumps Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Corrosive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

Note:

3/2 C THR rubber lined slurry pumps and parts are only interchangeable with Warman®3/2 C AHR rubber lined slurry pumps and parts.Each member from our significant effectiveness gross sales team values customers’ wants and enterprise communication for OEM Customized China Agricultural Irrigation Diesel Engine Water Pump High Capacity Double Suction Pump Mine Dewatering Pump, We generally concertrating on creating new creative item to meet request from our clients everywhere in the world. Be a part of us and let’s make driving safer and funnier alongside one another!

OEM Customized China Double Suction Pump, High Pressure Pump, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |