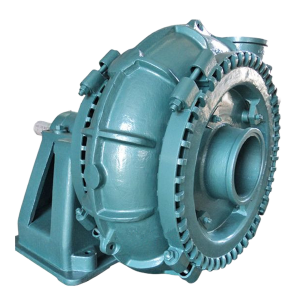

10/8F-TG Gravel Pump, Highly efficient and stable

10x8F-TG Gravel Pump is the world’s standard for dredge and gravel applications. The range provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. A wide variety of shaft seals provide a perfect fit for a wide range of applications. Pass very large solids not capable of being pumped by AH series slurry pumps.

Design Features

• G gravel pump uses modern CAD design method, and has excellent hydraulic performance, high efficiency, and low wear rate.

• G gravel pump has wide runner, good anti-clogging performance, and excellent cavitation performance.

• G gravel pump uses expeller and filler combined seal and mechanical seal, ensuring that the slurry doesn’t leak.

• The reliability design greatly improves mean time between failures (MTBF) of complete machine.

• G gravel pump uses thin oil lubrication metric bearing, and rationally sets lubrication and cooling system to ensure that the bearing operates at low temperature.

• Flow passage components are made of special materials, so they have good wear resistance and corrosive resistance; after special processing, they are used for seawater dusting, and seawater and salt mist electric chemical corrosion conditions.

• In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa.

10/8F-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

10/8F-TG |

260 |

216-936 |

8-52 |

400-800 |

65 |

3-7.5 |

533 |

10/8 Gravel Sand Pump Parts Structural

|

Base Code |

Part Name |

10/8F-TG |

10/8S-G |

10/8S-GH |

|

003 |

Base |

F003M |

S003M |

S003M |

|

005 |

Bearing Assembly |

F005M |

S005 |

S005 |

|

013 |

Door |

FG108013 |

FG108013 |

FGH8013 |

|

024 |

End Cover |

F024 |

S024 |

S024 |

|

028 |

Expeller |

F028 |

F028 |

FH028 |

|

029 |

Expeller Ring |

F029 |

F029 |

FH029 |

|

032 |

Adaptor Plate |

FG8032M |

FG8032M |

FGH8032 |

|

041 |

Back Liner |

FG8041 |

FG8041 |

FGH8041 |

|

044 |

Gland |

F044 |

F044 |

F044 |

|

062 |

Labyrinth |

F062 |

S062 |

S062 S062DM |

|

063 |

Labyrinth Ring |

F063 |

F063 |

F063 |

|

064 |

Impeller O-ring |

|||

|

067 |

Neck Ring |

F067 |

F067 |

F067 |

|

073 |

Shaft |

F073M |

S073 |

|

|

075 |

Shaft Sleeve |

F075 |

F075 |

F075 |

|

078 |

Stuffing Box |

F078 |

F078 |

FH078 |

|

108 |

Piston Ring |

F108 |

||

|

109 |

Shaft O-ring |

F109 |

F109 |

F109 |

|

111 |

Packing |

F111 |

F111 |

|

|

117 |

Shaft Spacer |

F117 |

F117 |

FG117 |

|

118 |

Lantern Restrictor |

F118 |

F118 |

F118 |

|

122 |

Expeller Ring/Stuffing Box Seal |

F122 |

FH122 |

F122 |

|

124 |

Bowl Sea/Door Seal |

FG10124 FG8124 |

FG10124 FG8124 |

G8124 |

|

130 |

Flange |

F10130 F8130 |

F10130 F8130 |

F10130 F8130 |

|

131 |

Bowl |

FG8131 |

FG8131 |

FGH8131 |

|

132 |

Discharge Joint Ring |

FG10132 F8132 |

FG10132 F8132 |

FG10132 F8132 |

|

134 |

Clamp Ring |

F134 |

F134 |

|

|

135 |

Clamp Ring |

F8135 |

F8135 |

FGH8135 |

|

137 |

Impeller |

FG8137 |

FG8137 |

FGH8137 |

|

138 |

Grease Cup Adaptor |

D138 |

D138 |

D138 |

|

221 |

Discharge Flange |

|||

|

239 |

Impeller Release Collar |

S239M |

||

|

292 |

Door Clamp Plate |

Note:

10×8 F-TG gravel pumps and spares are only interchangeable with Warman® 10×8 F-G gravel pumps and spares.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |